End Effectors

With over 25 years of End of Arm Tooling (EOAT) experience Factory Supply has a long history of designing, engineering, and building custom systems with standard parts for your specific application. We combine innovation with experience in order to create an infinite variety of end effectors based on what functions you want them to serve in your facility.

Products

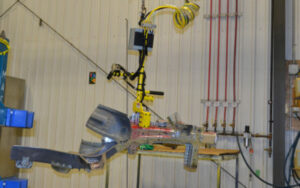

Pick and Place End Effectors

Pick and Place End of Arm Tooling systems specialize in moving one item from one location to another. They are perfect for companies that use mass production and increase the efficiency of the workplace.

Manual End Effectors

End Effectors can be operated in two different ways: manually or mechanically. Mechanically operated end effectors are perfect for operations that are simple and repetitive.

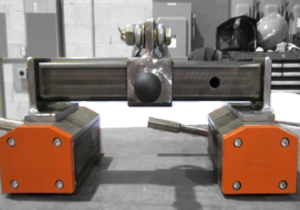

Magnetic End Effectors

These systems are ideal for moving large steel components like sheet metal, automotive or construction parts, machine dies and hydraulic cylinders.

Gripper End Effectors

Gripper End Effector Systems come in a variety of styles, including but not limited to the simple two-finger grippers which are used by the vast majority of industrial overhead lifting systems.

Clamp End Effectors

Clamp End Effectors specialize in picking up and moving items, these clamp end effectors have two metal pieces that tighten around a given item in order to lift it in the air and move it to the desired location.

Request a Quote

Ergonomic Material Handling

Cost-effective material handling solutions

Custom engineered systems

Meets or exceeds all OSHA and ANSI safety standards and regulations

Protect employees from workplace injuries and Musculoskeletal Disorders (MSD's)

Reduces the potential for costly fines and high insurance premiums

Improved productivity of workforce

Improved quality of work

Increase employee engagement and satisfaction

What our clients are saying

About Factory Supply

Projects

See if we have already solved the

problem you are having by viewing

the latest projects delivered by

Factory Supply.