Barrier Netting

As warehouses grow in size, and space is at a premium, more companies are forced to maximize storage of product by using up available vertical space. Stacking products to maximize vertical space now presents a big safety risk, as it does not utilize storage racking. Rather it is simply boxes stacked on top of boxes, often stored close to walkways or work areas. In the event that one of these stacks collapses or is knocked over by a forklift, the results can be catastrophic.

Engineered barrier netting systems provide protection against falling materials by installing netting systems along walkways or near workstations where employees are working. Not only will these systems protect employees but they will also help to limit and control access to materials.

Our systems are designed based on the total height of coverage, weights of each stacked box and total length of coverage. Freestanding or Floor-to-Ceiling posts are engineered and installed for each application to mount cables and netting to surround the stacked materials.

- AIRCRAFT CABLE (GALVANIZED CABLE)

- 1/4” AirCraft CABLE

- 3/8″

- *options available to use only cables as barrier

- NETTING PANEL

- 2500 lbs net – 2” square, industrial safety netting

- 3000 lbs net – 2” square, industrial safety netting

- 6000 lbs net – 2-½” square, fall arrest netting

- *net sizing may vary

- STANDARD RIGGING

- Wire Rope Clips

- Thimbles

- Turnbuckles

- Eyebolts

- Safety Snap Hooks

- POSTS

- Include installation hardware

- Fire retardant in accordance with NFPA701.

Custom net sizes based on each project

Material:

- 2500 lbs net – nylon

- 3000 lbs net – nylon

- 6000 lbs net – HTPP

- Knotless netting, sewn rope border

- U.V. protection

- Colour: black (custom available for large orders)

All bulk stacking applications

Netting panels are treated to meet NFPA 701 standards for fire-retardancy and have been tested and rated in accordance with ANSI A10.11 and OSHA safety standards.

Netting Systems

Customized systems fit to your facility needs

Protects employees from injury or death from falling objects

Reduces the potential for costly fines and high insurance premiums

Cost effective safety solution

Meets or exceeds all OSHA Safety standards

Safe and reliable engineered solution

Protects passersby from injury or death from falling objects

Reduces the potential for costly litigation

Request a Quote

Soft Catch Netting

Our netting is a soft catch product that absorbs energy as an object falls into it. The system disperses energy from impact point to guard frame, cable, and attachment points. Unlike rigid barriers, our nets are allowed to flex at impact, dissipating energy, and providing less excess force to the netting system itself, keeping your personnel and materials safe.

Engineering and Design Consultations

We meet all your custom project needs from start to finish. Our in-house engineering team will ensure quick sign-off on all custom orders and testing while meeting the exact specifications required for your equipment.

You can expect top-of-the-line products and excellent customer service. From design to installation, our team will walk you through the process and help you reach the best solution for your facility needs.

To request a consultation, please click here, and we’ll get back to you as soon as possible.

Safety Stats

What are the risks?

In 2018 there were 786 fatalities from being struck by a falling object or equipment, 325 were caused by a falling object.

I fact, the top 2 leading causes of workplace injuries in North America are slips, trips and falls and struck by objects.

- 137,650 injuries from being struck by falling objects or equipment

- 16,070 injuries from falls off of trucks

- 22,020 construction fall injuries

- 1750 fans injured every year by foul balls in mlb ballparks

What’s the cost?

- $41,000 per medically consulted injury

- $7,277,090,000 in direct costs in 2018 alone

Become A Distributor

Offer a wide range of high-quality engineered netting solutions to your customers.

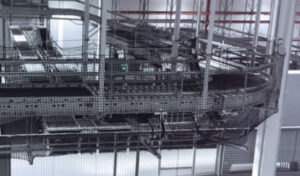

Conveyor Netting

Factory Supply offers custom conveyor guard netting systems tailored to your facilities operational needs. Aerial Conveyor safety has been an increasing concern in America.

Rack Netting Systems

Our Industrial Rack Netting is installed on the back of storage racking to protect aisle ways, work areas, and machinery from products that may become dislodged and fall to the ground below.

Gargoyle Rooftop Guardrail

A versatile, economic and modular fall protection system designed to protect employees performing job functions near the edge.