Truck Netting Systems

Classic Column Mount Truck Netting System

Components

- 3 column mount brackets (consist of 2 plates)

- 3/8-inch galvanized GAC

- Snap hooks for every 2 ft

- Stake pockets for every 2 ft

- 2 3/8-inch light duty thimble

- 1 net panel

- 4 3/8-inch wire rope clips

- 1 TB (6-inch x half inch)

Flange Mount Truck Netting System

Components

- 3 flange mount brackets (consist of 3 plates)

- 3/8-inch galvanized GAC

- Snap hooks for every 2 ft

- Stake pockets every 2 ft

- 2 3/8-inch light duty thimble

- 1 net panel

- 4 3/8-inch wire rope clips

- 1 TB (6-inch x half inch)

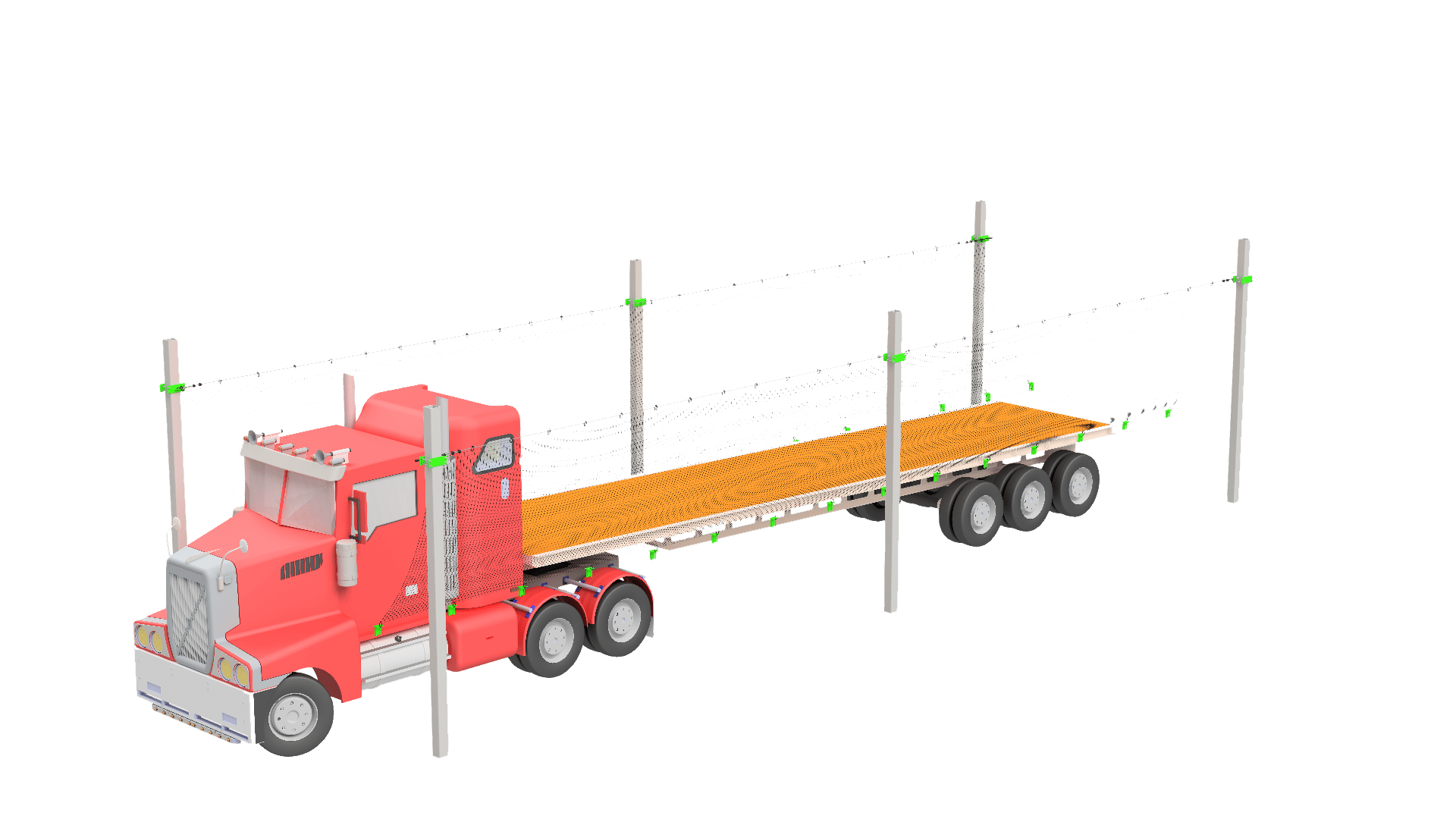

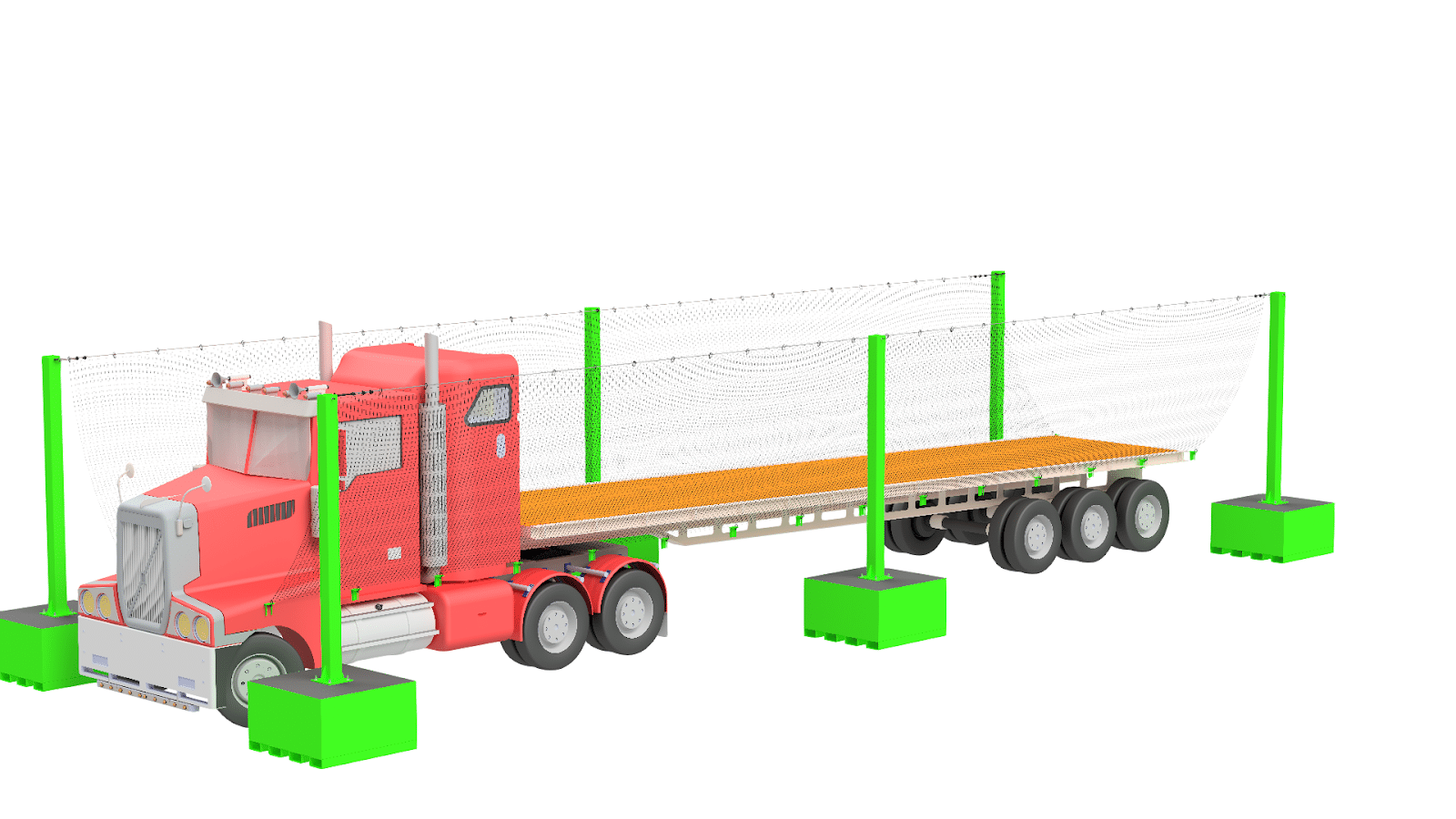

Fixed Base Portable Truck Netting System

Components

- 3 columns (6-inch x 6-inch)

- Column base (4 ft x 4 ft x 2.5 ft)

- 3/8-inch galvanized GAC

- Snap hooks for every 2 ft

- 2 3/8-inch light duty thimble

- 1 net panel

- 4 3/8-inch wire rope clips

- 1 TB (6-inch x half inch)

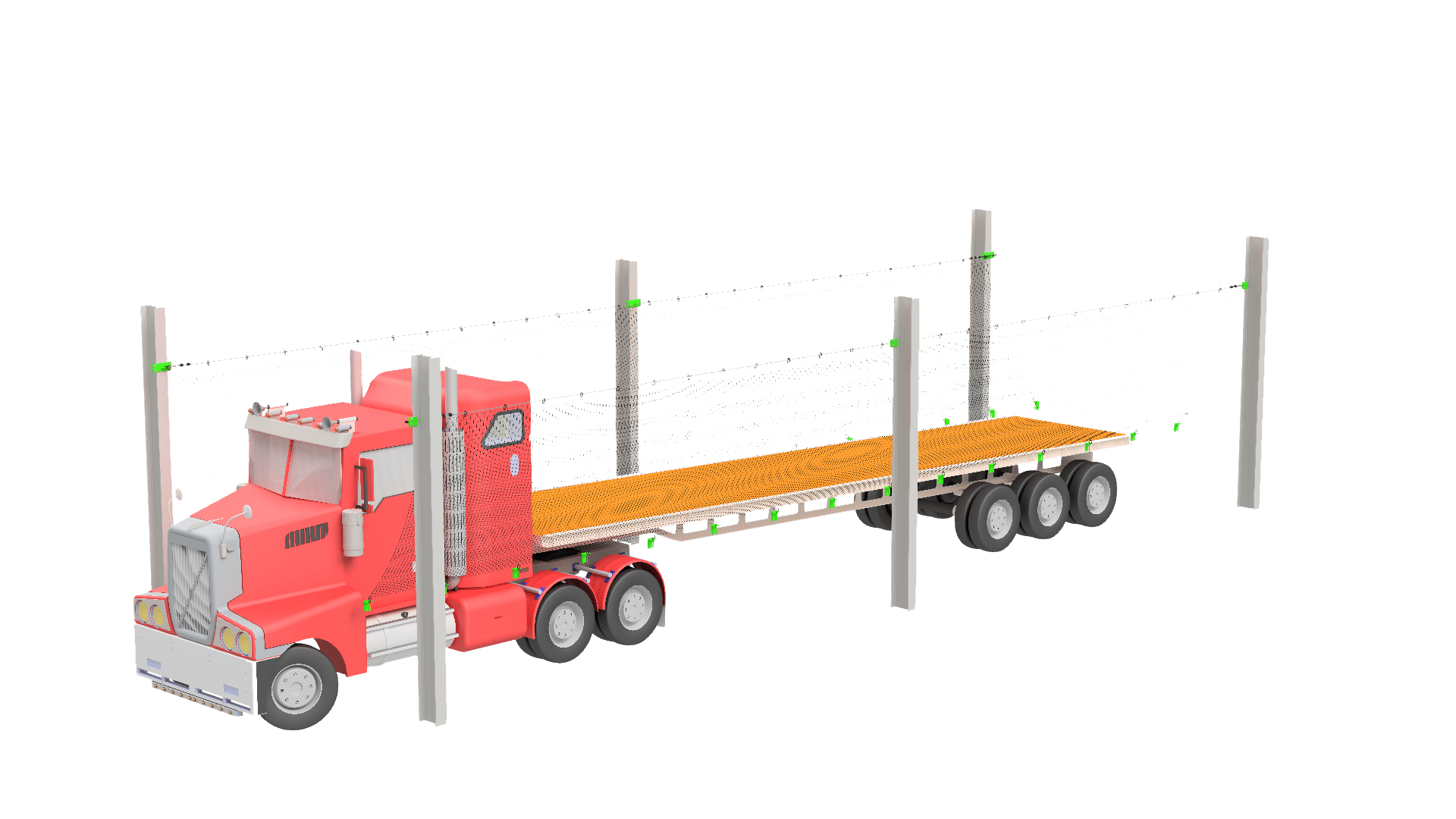

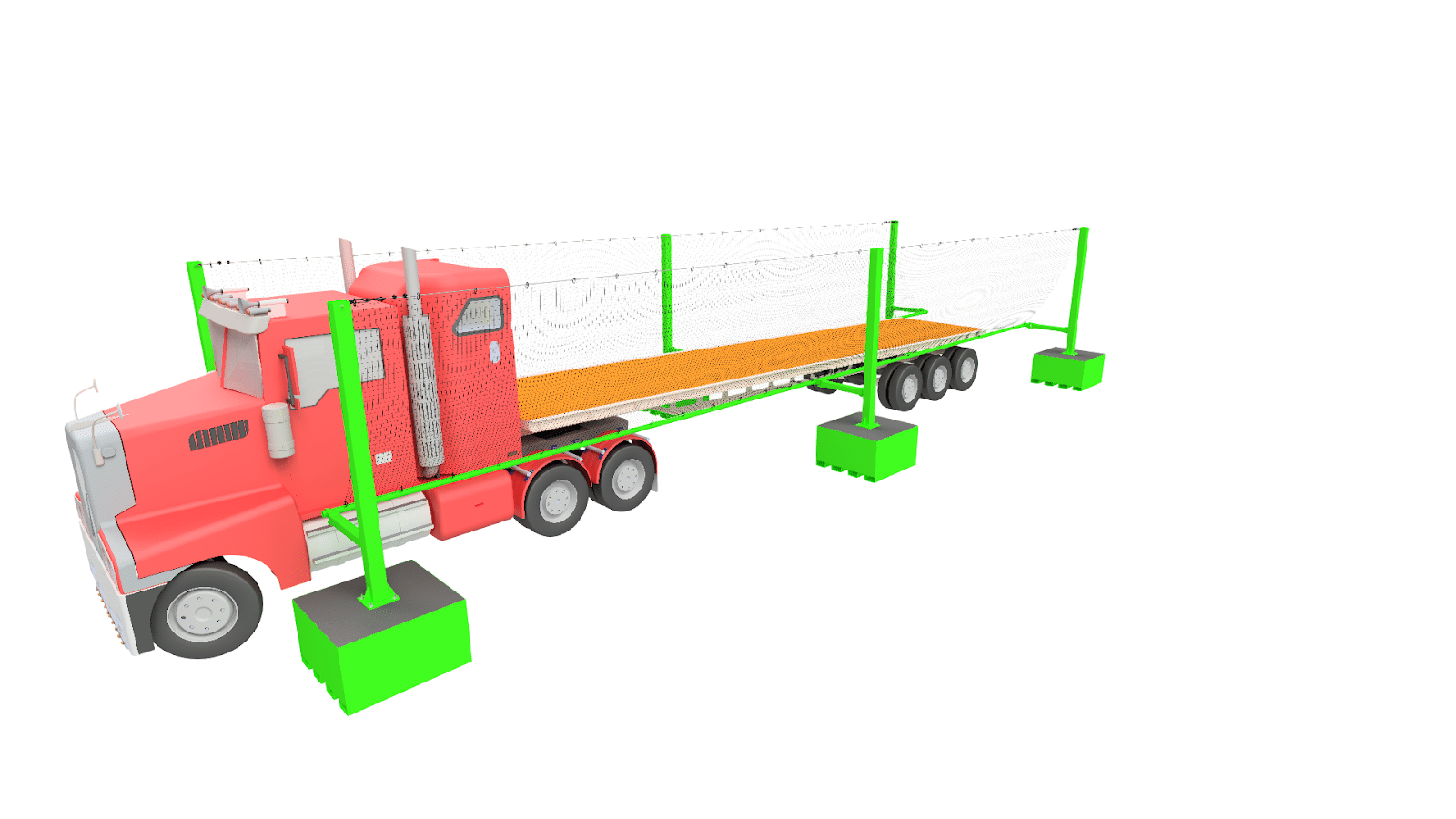

Pivoting Portable Truck Netting System

Components

- 3 columns (6-inch x 6-inch)

- Pivoting arm

- Compression bar (made up of three bars)

- Column base (4 ft x 4 ft x 2.5 ft)

- 3/8-inch galvanized GAC

- Snap hooks for every 2 ft

- 2 3/8-inch light duty thimble

- 1 net panel

- 4 3/8-inch wire rope clips

- 1 TB (6-inch x half inch)

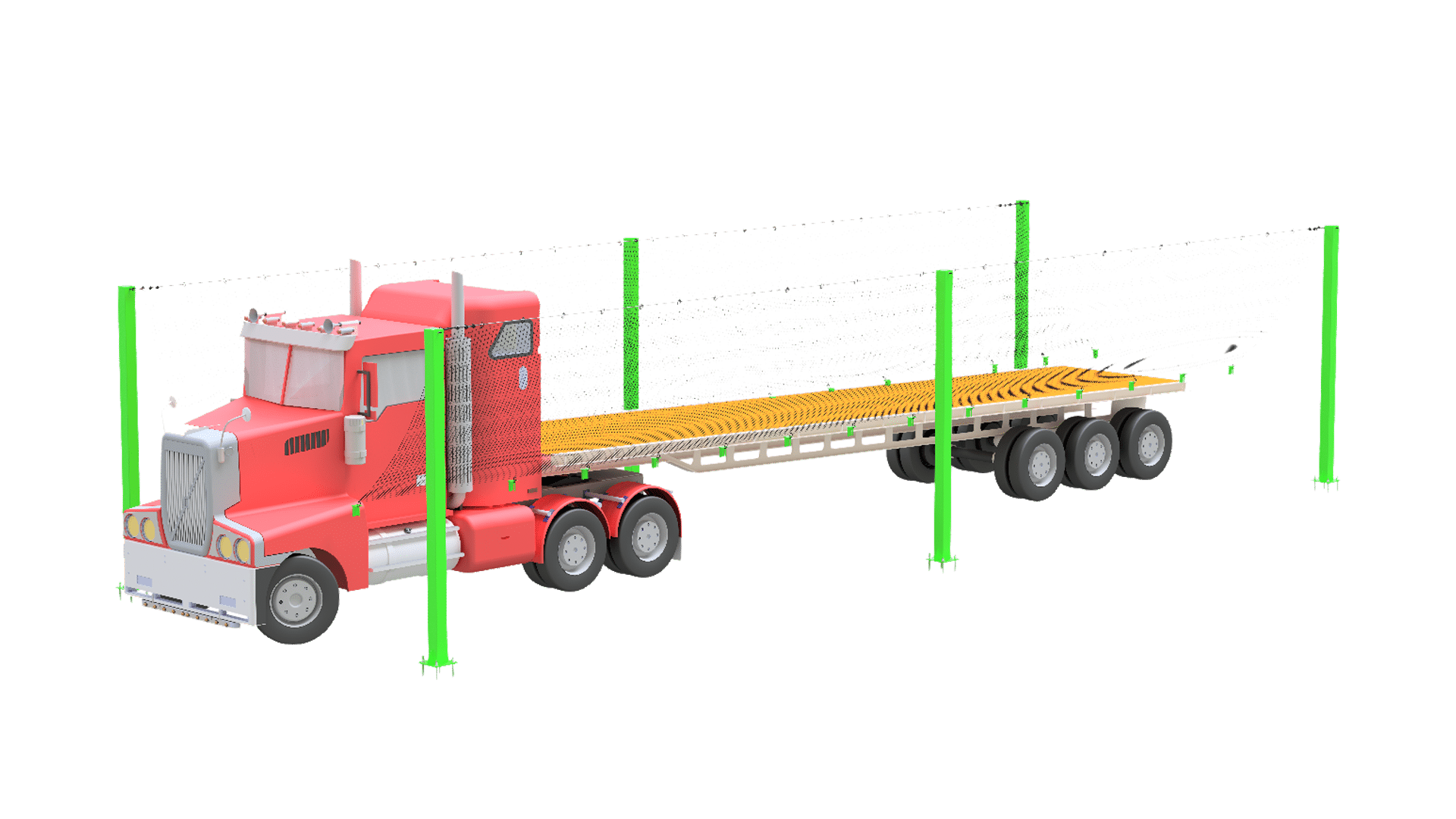

Classic Free Standing Truck Netting System

Components

- 3 columns (6-inch x 6-inch)

- 3/8-inch galvanized GAC

- Snap hooks for every 2 ft

- Stake pockets every 2 ft

- 2 3/8-inch light duty thimble

- 1 net panel

- 4 3/8-inch wire rope clips

- 1 TB (6-inch x half inch)

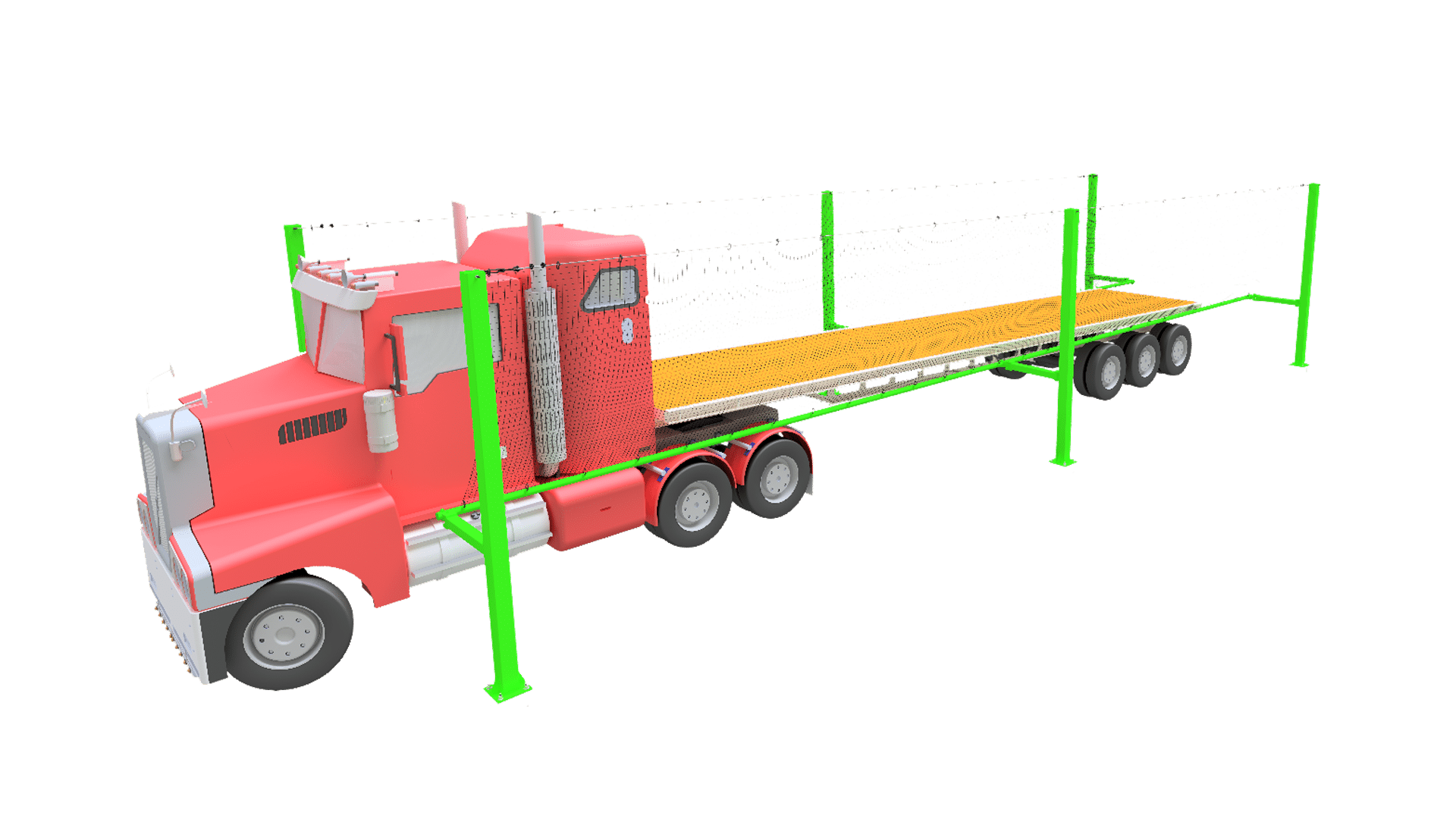

Pivoting Free Standing Truck Netting System

Components

- 3 columns (6-inch x 6-inch)

- Pivoting arm

- Compression bar (made up of three bars)

- 3/8-inch galvanized GAC

- Snap hooks for every 2 ft

- 2 3/8-inch light duty thimble

- 1 net panel

- 4 3/8-inch wire rope clips

- 1 TB (6-inch x half inch)

Components

- Snap hooks for every 2 ft

- Stake pockets every 2 ft

- 1 net panel

- Flat bar along length of bay

Netting Specifications

| Specification | Details |

|---|---|

| Product Name | Truck Safety Netting |

| Manufacturer | Factory Supply |

| Safety Standards Compliance |

OSHA MOL ANSI WorkSafeBC OBC NBC CSA BS EN CE Certification |

| Netting Panel |

3000 lbs net – 2” square, industrial safety netting |

| Netting Colour |

Black Yellow Custom colours are available for large orders |

| Netting Material |

3000 lbs net – nylon |

| Netting Cable | 1/4” aircraft cable |

| Netting Design |

Knotless netting Sewn rope border U.V. protection |

Netting Safety and Regulations

To ensure compliance with regulations, we advise following safety net installation standards. This includes obtaining certification from qualified installers or engineers, conducting testing procedures, maintaining thorough records, and providing worker training.

A comprehensive fall protection plan must consider work nature, site or facility conditions, load capacity, and manufacturer specifications. Proper installation, maintenance, and regular inspection are critical for compliance and effectiveness.

Accumulated debris can compromise the functionality of safety nets and create hazards. Work operations should pause promptly to remove debris or any fallen objects to maintain optimal net performance.

Resources

Netting

Catalogue

Find details about all of our netting systems in our Netting Catalogue.

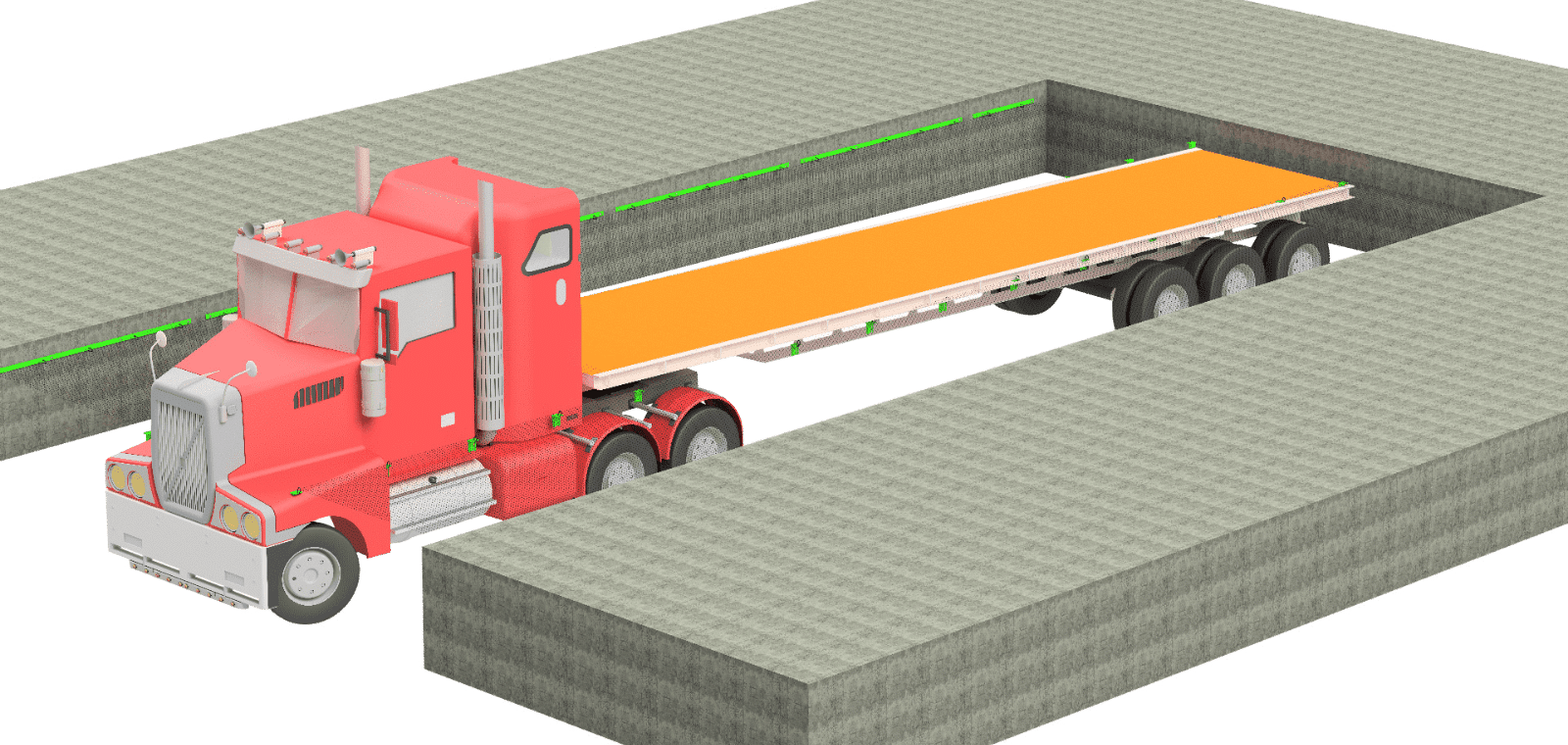

Truck Netting

Info Sheet

Learn more about the features and benefits of our flatbed truck netting systems.

Netting

Overview

Learn the benefits to choosing to provide our safety netting systems to your clients.

Your Perfect Solution Awaits!

Passive Vs Active Fall Protection

Passive Fall Protection

Active Fall Protection

Netting Systems

Customized systems fit to your facilities specific needs

Protects employees from injury or death from falls

Reduces the potential for costly fines and high insurance premiums

Cost effective safety solution

Meets or exceeds all OSHA safety standards

Safe and reliable engineered solution

Protects passersby from injury or death from falling objects

Reduces the potential for costly litigation

Become A Distributor

Offer a wide range of high-quality engineered netting solutions to your customers.

Factory Supply

Details about all of our Netting systems can be found in our Netting Catalogue along with safety statistics and other info.

Supplier of Working at Heights Protection, Aviation Access Products, Netting Safety Systems and Engineering Services across the USA.

We focus on creating turnkey solutions that allow your employees to do their jobs safely while protecting your company.