Roll Handling Equipment

Moving rolls and reels through your facility can present a number of different health and safety issues. One of the main issues is the need for lifting, rotating and turning these objects safely. Roll handling equipment can help eliminate back, joint and muscle injuries while increasing production output.

Factory Supply carries a number of roll handling solutions that are designed to specific standards with engineered safety factors that solve a wide variety of roll handling issues.

Factory Supply has ergonomic material handling specialists on hand that can walk you through finding the right solution for your facility. They can help you identify the different factors that can change which piece of equipment might work best in a given space. Allowing you to “plan ahead” and take a wholistic approach that considers the current and future states of your facility

Products

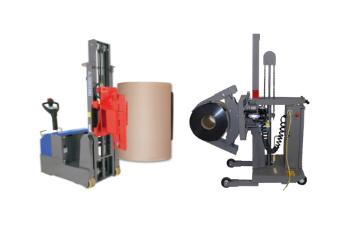

Heavy Duty Core Gripping Roll Handlers

Heavy Duty Core Gripping roll handlers are used to lift, move, and reorient rolls that weigh 500 lbs. or more. These pieces of equipment can be designed to perform a number of functions.

![img light duty core gripping roll handler [schlumpf]](https://www.factorysupply.com/wp-content/uploads/2021/10/img-light-duty-core-gripping-roll-handlers-v2.png)

Light Duty Core Gripping Roll Handlers

Light Duty Core Gripping roll handlers are used to lift, move, and reorient rolls that weigh from 0 lbs. to 500 lbs. These pieces of equipment can be designed to perform a number of functions.

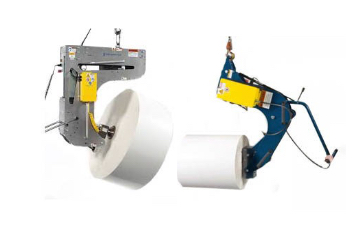

Heavy Duty Outside Clamping Roll Handlers

Heavy Duty Outside Clamping roll handlers are used to lift, move, and reorient rolls that weigh 500 lbs. or more. These pieces of equipment can be designed to perform a number of functions.

Light Duty Outside Clamp Roll Handlers

Light Duty Outside Clamping roll handlers are used to lift, move, and reorient rolls that weigh up to 500 lbs. These pieces of equipment can be designed to perform a number of functions.

Forklift Roll Handling Attachments

Various forklift attachments can be used to safely perform different functions while handling rolls. These forklift roll handling attachments are inserted into the core of the roll.

Below the Hook Roll Handling Attachments

Factory Supply’s extensive line of Hoist Roll Handling Solution models come in both core gripping and cradle formats which give operators the ability to lift and turn a roll with ease.

Roll Movers

Roll movers, carts and dollies are designed to safely transport rolls throughout your facility safely to drop off and pick up points without the need for an extensive network of cranes or conveyors.

Roll Handling Attachments

Although there are a variety of different roll handing solutions for a number of different scenarios, there are some specific circumstances that require some customization.

Talk to a specialist today

KEY FEATURES

Cost-effective solutions

Engineered for performance without compromising your budget.

Safety First

Reduces risk of injuries and Musculoskeletal Disorders (MSDs).

Customized Systems

Tailored solutions designed to fit the unique needs of your workspace.

Workforce productivity

Improves efficiency and output across all workplace operations.

Employee engagement

Boosts satisfaction and involvement by providing safer & convenient equipment.

Compliance

Meets and exceeds all OSHA and ANSI standards for workplace safety.

Cost savings

Minimizes potential fines and lowers insurance premiums through safer practices.

Quality assurance

Enhances the overall quality and consistency of work performed.

Projects

![IMG 4736 e1535051537200 scaled 1 e1632751526710 Line cart mover system [material handling]](https://www.factorysupply.com/wp-content/uploads/elementor/thumbs/IMG_4736-e1535051537200-scaled-1-e1632751526710-pjt5yzyrk43rxzmd66c8my37mgr67nn14jymwf9lmo.jpg)

Linen cart

mover system

A battery-powered cart mover with a custom hitch was supplied to allow a single operator to safely and efficiently move heavy linen carts throughout the facility.

Fixed Access Ladder

and Rooftop Guardrail

A fixed access ladder with an integrated guardrail safety system was manufactured and installed to provide safe, compliant rooftop access and egress.

![869 1 Warehouse rack netting solution install [rackguard]](https://www.factorysupply.com/wp-content/uploads/elementor/thumbs/869-1-pjt5v13apao6x9dwcgky3y55bwbdpnvtwwstyd5fwg.jpg)

Warehouse netting

solution install

Designed and installed custom RackGuard netting solutions to fit unique shelving configurations, providing durable, cost-effective protection for both equipment and personnel.

Television Broadcast

Stand

Engineered and fabricated a custom lightweight aluminum broadcast stand, designed for multiple users and fixed installation, meeting all relevant safety standards.

Your Perfect Solution Awaits!

Related Products

Material handling

Ergonomic material handling solutions engineered for safety, productivity, and lasting workplace efficiency.

NETTING SAFETY Systems

Our netting systems have been designed to meet all required safety measures to reduce injuries and liability.

Rooftop Safety

Products

Reliable rooftop safety solutions designed for compliance and protection.