Light Duty Outside Clamp Roll Handlers

Clamp gripping roll handlers use a clamping mechanism that grips the outside of the roll. For some products this mechanism will damage the roll (see Light Duty Core Gripping).

Light Duty Outside Clamping roll handlers are used to lift, move, and reorient rolls that weigh up to 500 lbs.

These pieces of equipment can be designed to perform a number of functions, the two main functions are;

Horizontal

Roll handlers that are designed mainly to move a roll from one point to another without having to change the horizontal orientation of a roll. The clamp fits on the outside of the roll and can move the roll up or down, forward or back, side to side.

Lift, turn, and rotate

Roll handlers that are designed to change the orientation of a roll. This can be to turn, rotate, and lift. The clamp fits on the outside of the roll and the roll can be turned from a horizontal to vertical orientation, rotated in tight spaces, or between different machinery, among many other practical uses.

Injury incident : Accident Report Detail

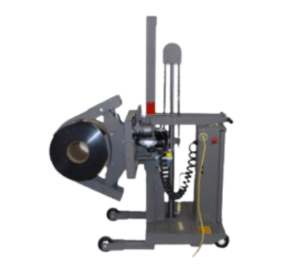

Squeeze-O-Turn 12133 Series Outside Clamp Roll Handler

The Double Mast Squeeze-O-Turn automatically centres loads onto the Lift-O-Flex and can handle loads up to 400 pounds. This is done through the use of three squeeze masts, two of which are electrically powered and one is not. The squeeze masts work together to grip and ungrip loads and have a total of 22 inches of arm mobility.

Squeeze-O-Turn 12120 Series Roll Handler

This piece of roll handling equipment is a combination of the Lift-O-Turn and the Lift-O-Squeeze. The result of this combination is a product that assists in providing ergonomic load handling for rotating and lifting barrels, rolls, buckets, boxes and drums. The Squeeze-O-Turn Arms hold the product(s) in place throughout rotation, transport and lifting to ensure that product handling is handled with a controlled, gentle force.

Lift-O-Squeeze 12134 Series Roll Handler

The 12134 Lift-O-Squeeze is designed for the Lift-O-Flex series of Ergonomic lifters. This device makes use of standard components to create a product that does it all when it comes to lifting rolls, drums, cartons and barrels weighing up to 170 pounds. The Lift-O-Squeeze adapts to different load sizes and is easy to configure. It will also never damage the products that it works with due to its gentle and controllable force throughout the entire operating process.

EasyLift ELDR Narrow Aisle Roll Manipulator

This piece of mobile roll handling equipment is perfect for moving rolls through narrow aisles within your facility and is able to manipulate rolls weighing up to 500 lbs. This roll handling system also has a foot floor lock ensuring that this roll handing system is safe to use. With 360 degrees rotation and a power clamp and lift you can be assured that this roll handling system will optimize your workplace efficiency while also preventing employee injuries.

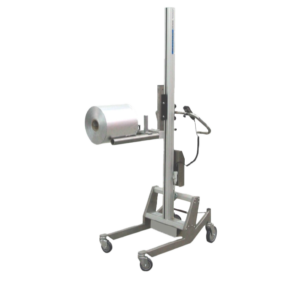

EasyLift Roll Transporter

This roll transporter will enable you to optimize your roll handling process with the option of an aluminum roll post or stainless steel V-Pans, enabling you to safely move rolls throughout your facility. This roll handling system is designed to be able to rotate with manual rotation.

The V-Pans are built to accommodate rolls sizes up to 30” in diameter and can weigh up to 600 lbs, these pans have the ability to be lowered to floor level, which will allow for the roll to drop from the roll handling unit onto a standard pallet. Rolls can be manually rotated left and right to aid in the placement on converting machines, the degree of rotation available depends upon the roll width.

Off Set Rotating V Block Roll Handler

Do you need to handle rolls with multiple drop-off locations? The Off Set Rotating “V” Block roll handling unit allows rolls to be rotated up to 90-degrees. Cross roll handling is achieved by rotating rolls onto spindles or a shaft can be inserted for off-loading to bearing blocks.

Sliding Forks 13200 Series Roll Handler

This roll handling device is designed with sliding forks which allows for the operator to manually extend and retract the forks with the roll on it. This roll handling unit allows for the user to manipulate rolls up to 60 pounds with approximately a 10” stroke. This roll handling unit can be used for a variety of different applications and industries such as manufacturing and automotive, food and beverage, pharmaceutical, hospital, warehouse, and retail.

Lift-N-Glide Hybrid Lifter

The Lift-N-Glide is unique in the variety of load handling characteristics it contains. Though the Lift-N-Glide was primarily designed for roll handling, it does not just stop there; with the correct end effector it is able to complete a number of different tasks including lifting and moving products onto racking systems including Drum Handling applications.

– 360° Swivel for load handling access

– Handlebar is adjustable by the operators to achieve ergonomic operation

– Standard and custom length lift masts

Models

- Drastic reduction in heavy/repetitive lifting

- Customized for your specific application, designed to work with your product(s)

- Reduction in workplace illness/injury claims, resulting in lower insurance costs

- Allows for diversity/adaptability on the job, more workers are now able to complete the task without physical limitations being an issue

- Our systems pay for themselves via productivity and efficiency increases

- Weight and capacity ranges are considered during the design process, our systems can handle multiple weights, textures and products without altering the system

- Designed to work in your specific facilities conditions, such as high heat, dust, humidity, moisture etc.

- Pulp and Paper

- Textile

- Packaging

- Pharmaceutical / Medical

- Food and Beverage

- Manufacturing

All of our Roll Handling solutions either meet or exceed all applicable regulations which include; OSHA, ANSI and ASME B30.20.

- Schlumpf

- Armanni

- R on I

- Paper

- Plastic

- Film

- Textiles

- etc

Your Perfect Solution Awaits!

Related Products

Roll Handling Attachments

Although there are a variety of different roll handing solutions for a number of different scenarios, there are some specific circumstances that require some customization.

Conveyor Netting

Factory Supply offers custom conveyor guard netting systems tailored to your facilities operational needs. Aerial Conveyor safety has been an increasing concern in America.

Pallet Risers and Steel Pallets

Durable pallet products that are designed to work together with devices like roll handlers, drum handlers and other specific ergonomic devices. These pieces of equipment come with legs that stick out on either side.

About Factory Supply

Projects

See if we have already solved the

problem you are having by viewing

the latest projects delivered by

Factory Supply.