Roll Handling Attachments

Although there are a variety of different roll handing solutions for a number of different scenarios, there are some specific circumstances that require some customization.

For these needs, we offer a line of roll handling accessories that solve specific problems for the end user.

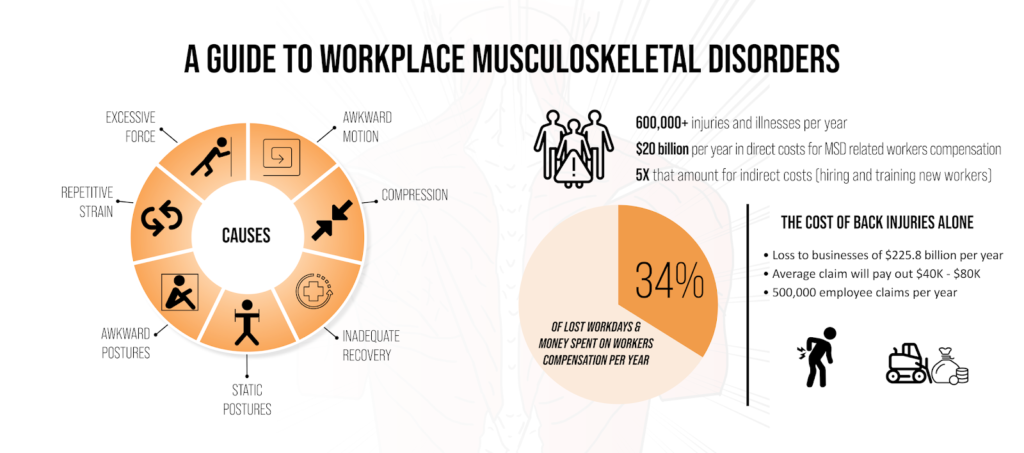

Injury incident: Accident Report Detail

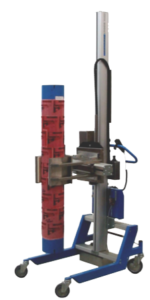

Cloth Roll Handling Attachment

Designed for handling cloth rolls and attaches to the Lift-O-Flex series of lifters.

It comes with two options based on your needs;

Vertical to horizontal – Uses the Squeeze-O-Turn end effector combined with long grippers to reorient cloth rolls from a vertical to horizontal position.

Horizontal to horizontal – Uses fixed forks with a with a “v” block or core probe to move rolls from pallets directly onto the “v” block.

Flexographic Plate Attachment

Flexographic sheath that fits around the outside of a roll that minimizes any damage that may be caused by roll handling.

Tip Module

Designed to offer an additional axis of movement for roll handling devices which allows for the elevation changes needed for load pick up and drop off.

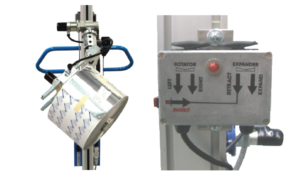

Anti-telescopic roll handling attachment

Designed for Lift-O-Flex and Expand-O-Turn roll handling systems. It has the option of being used with electric or manual powered systems and comes in custom or standard sizes.

The attachment itself is manually operated and used to stabilize rolls before they are rotated for placement onto spindles.

Adjustable Core Probe Attachment

Allows for rolls requiring offset loading to be loaded onto spindles. It also allows for the same core probe that is used for centre access to be adjusted to the right or left position.

Electric Roll Handling Kit

Optional, electric powered rotating tip that allows the operator to rotate rolls by their core from the vertical to the horizontal position and vice versa.

Telescopic Mast Kit

Used for reaching heights that are higher than normal while also being able to travel through doors and other impediments in your facility.

Models

- Drastic reduction in heavy/repetitive lifting

- Customized for your specific application, designed to work with your product(s)

- Reduction in workplace illness/injury claims, resulting in lower insurance costs

- Allows for diversity/adaptability on the job, more workers are now able to complete the task without physical limitations being an issue

- Our systems pay for themselves via productivity and efficiency increases

- Weight and capacity ranges are considered during the design process, our systems can handle multiple weights, textures and products without altering the system

- Designed to work in your specific facilities conditions, such as high heat, dust, humidity, moisture etc.

- Pulp and Paper

- Textile

- Packaging

- Pharmaceutical / Medical

- Food and Beverage

- Manufacturin

All of our Roll Handling solutions either meet or exceed all applicable regulations which include; OSHA, ANSI and ASME B30.20.

- Schlumpf

- Armanni

- R on I

- Paper

- Plastic

- Film

- Textiles

- etc

Your Perfect Solution Awaits!

Related Products

Pallet Risers and Steel Pallets

Durable pallet products that are designed to work together with devices like roll handlers, drum handlers and other specific ergonomic devices. These pieces of equipment come with legs that stick out on either side.

Below the Hook Roll Handling Attachments

Factory Supply’s extensive line of Hoist Roll Handling Solution models come in both core gripping and cradle formats which give operators the ability to lift and turn a roll with ease.

Barrier Netting

Engineered barrier netting systems provide protection against falling materials by installing netting systems along walkways or near workstations where employees are working.

About Factory Supply

Projects

See if we have already solved the

problem you are having by viewing

the latest projects delivered by

Factory Supply.