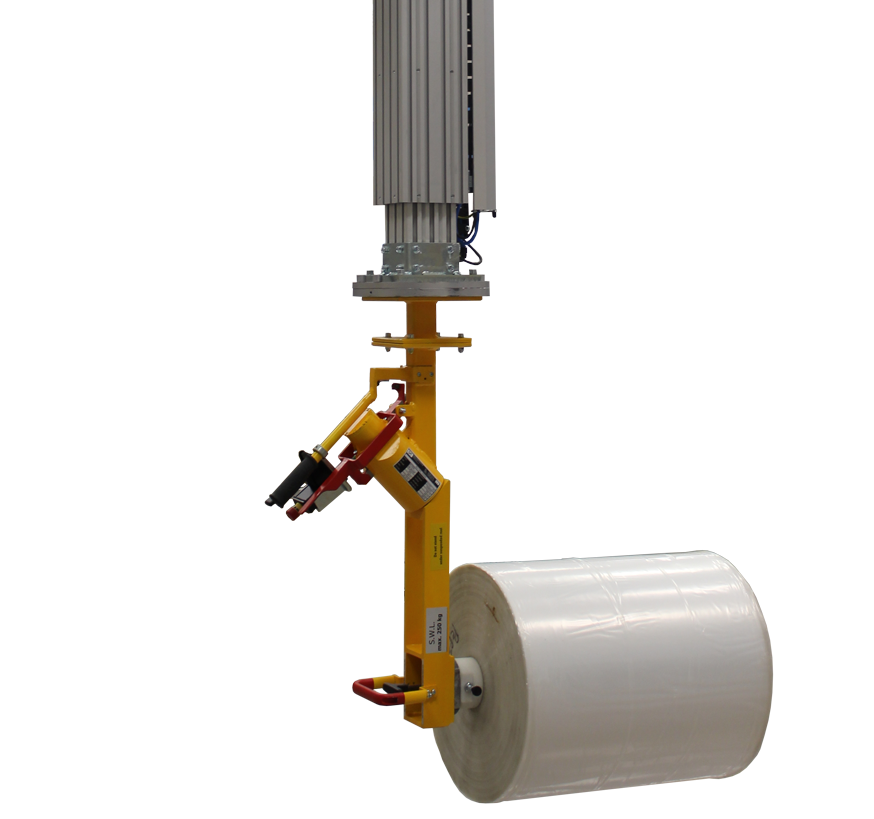

Below the Hook Roll Handling Attachments

For facilities that have existing cranes and hoists, there are a number of below the hook attachments that are specific to roll handling.

Factory Supply’s extensive line of Hoist Roll Handling Solution models come in both core gripping and cradle formats which give operators the ability to lift and turn a roll with ease so they can minimize injuries as well as material damage while boosting your productive capacity.

Choosing the correct system for your needs is based on a number of different usage, environmental, and capacity factors. Our wide variety of Hoist Roll Handling Solutions fall into three main categories:

Lift and Turn Handlers

Core based roll handlers that lift, turn and rotate rolls

Vertical Roll Lifters (VRLs)

Core based roll handlers that pick up your roll by the core from a vertical orientation (perpendicular to the ground)

Horizontal Roll Lifters (HRLs)

Core based roll handlers that pick up your roll by the core from a horizontal orientation (parallel to the ground)

Injury incident: Accident Report Detail

Light Duty Below the hook attachments

Roll lifters designed for smaller rolls weighing from 0 lbs. to 500 lbs. These hoist based roll lifters come with options like modular design, integrated probe tooling for gripping rolls by their core, pneumatic or electric power and auto leveling. Different roll handling units have flexible designs which allow for units to be optimized for each individual product usage.

By lifting rolls by the core, roll handling units are able to keep valuable products protected from damage and lessen the risk of operator injury.

Hoist based roll lifters have a turning function, enabling operators to turn loads with minimal effort and no external power source.

| Model | Designed for | Movement | Weight Capacity | Number of Users | Controls | Gripping Mechanism | Roll Sizes | |

|---|---|---|---|---|---|---|---|---|

MRT 150

| Lifting and moving rolls | Manual | 150 lbs. | 1 | Push buttons | Core gripping | Request a Quote | |

MRT 330 AL ADJ

| Lifting and moving rolls | Manual | 300 lbs. | 1 | Push buttons | Core gripping | Request a Quote | |

HRL 200 P

| Lifting and moving rolls | Manual | 200 lbs. | 1 | Push buttons | Core gripping | Max. Width 18″ – 41″ and Max Diameter of 28″ | Request a Quote |

HRL 330 AL

| Lifting and moving rolls | Manual | 330 lbs. | 1 | Push buttons | Core gripping | Request a Quote | |

PRT 300

| Lifting and moving rolls | Manual | 300 lbs. | 1 | Push buttons | Core gripping | Request a Quote | |

L1 Electric Tip Lift

| Lifting and tipping rolls | Manual | 115 lbs. | 1 | Handle mounted push buttons | Core gripping | various | Request a Quote |

L2 Pneumatic Tip Lift

| Lifting and tipping rolls | Manual | 175 lbs. | 1 | Handle mounted push buttons | Core gripping | various | Request a Quote |

L3 Pneumatic Tip Lift

| Lifting and tipping rolls | Manual | 200 lbs. | 1 | Handle mounted push buttons | Core gripping | various | Request a Quote |

Heavy Duty Below the hook attachments

Roll lifters designed for larger rolls weighing from 500 lbs. to 5000 lbs. These hoist based roll lifters come with options like modular design, integrated probe tooling for gripping rolls by their core, pneumatic or electric power and auto leveling. Different roll handling units have flexible designs which allow for units to be optimized for each individual product usage.

These attachments come in both core gripping and cradle designs.

| Model | Designed for | Movement | Weight Capacity | Number of Users | Controls | Gripping Mechanism | Roll Sizes | |

|---|---|---|---|---|---|---|---|---|

MRT 500 AL ADJ

| Lifting and moving rolls | Manual | 500 lbs. | 1 | Push buttons | Core gripping | Request a Quote | |

HRL 250 C

| Horizontal lifting and moving rolls | Manual | 1000 lbs. | 1 | Push buttons | Cradle | Max Width 24″ and Max Roll Diameter of 28″ | Request a Quote |

HRL 1000 AL

| Lifting and moving rolls | Manual | 1250 lbs. | 1 | Push buttons | Core gripping | Max width of 45” | Request a Quote |

HRL 1000 C

| Horizontal lifting and moving rolls | Manual | 1000 lbs. | 1 | Push buttons | Cradle | Max width of 32” | Request a Quote |

PRT 500

| Lifting and moving rolls | Manual | 500 lbs. | 1 | Push buttons | Core gripping | Request a Quote | |

ERT 350 230VAC

| Lifting and moving rolls | Manual with a power source of 115V AC | 500 lbs. | 1 | Push buttons | Core gripping | Max Roll Width of 33″ and a Max OD of 36″ | Request a Quote |

ERT 600 230 VAC

| Lifting and moving rolls | Manual | 600 lbs. | 1 | Push buttons | Core gripping | Max Roll Width of 60″, Max Roll O.D. 48″ | Request a Quote |

VRL 500 TA

| Lifting and moving rolls | Manual, Swivel hoist hook equipped | 500 lbs. | 1 | Push buttons | Core gripping | 14.5″ x 9.1″ x 10.4″ | Request a Quote |

VRL 1000 3C

| Vertical lifting and moving rolls | Manual | 1000 lbs. | 1 | Push buttons | Core gripping | 10.1″ x 5.8″ x 10.4″ | Request a Quote |

VRL 1000 TA

| Vertical lifting and moving rolls | Manual | 1000 lbs. | 1 | Push buttons | Core gripping | Request a Quote | |

VRL 2200

| Vertical lifting and moving rolls | Manual | 2200 lbs. | 1 | Push buttons | Core gripping | Request a Quote | |

VRL 4400

| Vertical lifting and moving rolls | Manual | 4400 lbs. | 1 | Push buttons | Core gripping | Request a Quote | |

Mechlift

| Lifting and moving rolls | electric | 880 lbs | 1 | joystick | core gripping | Request a Quote | |

GW Self-Reel Feeder

| Lifting and turning rolls | electric | 1102 lbs. | 1 | Push Button | core gripping | Various | Request a Quote |

SW Self-Reel Feeder

| Lifting and turning rolls | electric | 1763 lbs | 1 | Mechanical | core gripping | Various | Request a Quote |

Super Duty Below the hook attachments

Roll lifters designed to lift rolls weighing 5000 lbs. plus. These hoist based roll lifters come with options like modular design, integrated probe tooling for gripping rolls by their core, pneumatic or electric power and auto leveling. Different roll handling units have flexible designs which allow for units to be optimized for each individual product usage.

These hoist based lifters work well for transporting dense or extremely heavy rolls throughout your facility.

| Model | Designed for | Movement | Weight Capacity | Number of Users | Controls | Gripping Mechanism | Roll Sizes | |

|---|---|---|---|---|---|---|---|---|

RHH Reel Lifter

| Horizontal Roll Lifting | Manual | 8800 lbs. | 1 | Push buttons | Core gripping | Able to Lift up Roll with Inside Grippers of 70mm, 76.2mm, 150mm, 152.4mm | Request a Quote |

AL Auto Lift

| Vertical Rolls | Manual | 8818 lbs. | 1 | Push buttons | Core gripping | Roll sizes between 30 mm – 650 mm | Request a Quote |

RH Reel Lifter

| Vertical Rolls | Manual | 8818 lbs. | 1 | Push buttons | Core gripping | Various | Request a Quote |

BW Self-Reel Feeder

| Lifting and Moving Rolls | Electro-Mechanic Drive | 11023 lbs. | 1 | Remote control | Core gripping | Various | Request a Quote |

Models

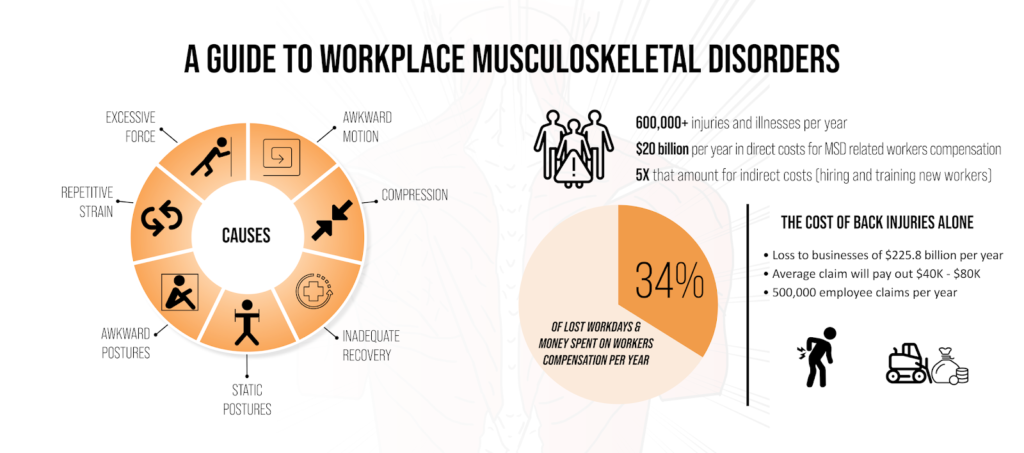

- Drastic reduction in heavy/repetitive lifting

- Customized for your specific application, designed to work with your product(s)

- Reduction in workplace illness/injury claims, resulting in lower insurance costs

- Allows for diversity/adaptability on the job, more workers are now able to complete the task without physical limitations being an issue

- Our systems pay for themselves via productivity and efficiency increases

- Weight and capacity ranges are considered during the design process, our systems can handle multiple weights, textures and products without altering the system

- Designed to work in your specific facilities conditions, such as high heat, dust, humidity, moisture etc.

- Pulp and Paper

- Textile

- Packaging

- Pharmaceutical / Medical

- Food and Beverage

- Manufacturing

All of our Roll Handling solutions either meet or exceed all applicable regulations which include; OSHA, ANSI and ASME B30.20.

- Schlumpf

- Armanni

- Bartholomy

- R on I

- Paper

- Plastic

- Film

- Textiles

- etc

Your Perfect Solution Awaits!

Related Products

Pallet Risers and Steel Pallets

Durable pallet products that are designed to work together with devices like roll handlers, drum handlers and other specific ergonomic devices. These pieces of equipment come with legs that stick out on either side.

Lift Tables and Positioners

Factory Supply has ergonomic material handling specialists on hand that can walk you through finding the right solution for your facility. They can help you identify what works best with your given space.

Barrier Netting

Engineered barrier netting systems provide protection against falling materials by installing netting systems along walkways or near workstations where employees are working.

About Factory Supply

Projects

See if we have already solved the

problem you are having by viewing

the latest projects delivered by

Factory Supply.