Sheet Handling Equipment

Lifting sheets safely is often a challenging material handling problem as sheets are often bulky, heavy, and can be prone to damage.

We offer a variety of vacuum sheet handling solutions designed in order to safely lift and move sheets made of a variety of materials.

The solutions we provide follow three distinct design principles: adaptability and flexibility, cost-effectiveness, and durability. Whether the solution you’re looking for is simply lifting, rotating or tilting, we have the products and expertise to get the job done.

- Drastic reduction in heavy/repetitive lifting

- Customized for your specific application, designed to work with your product(s)

- Reduction in workplace illness/injury claims, resulting in lower insurance costs

- Allows for diversity/adaptability on the job, more workers are now able to complete the task without physical limitations being an issue

- Our systems pay for themselves via productivity and efficiency increases

- Weight and capacity ranges are considered during the design process, our systems can handle multiple weights, textures and products without altering the system

- Designed to work in your specific facilities conditions, such as high heat, dust, humidity, moisture etc.

- Pulp and Paper

- Textile

- Packaging

- Pharmaceutical / Medical

- Food and Beverage

- Manufacturing

All of our Material Handling solutions either meet or exceed all applicable regulations which include; OSHA, ANSI and ASME B30.20.

Injury incident: Accident Report Detail

At approximately 8:50 a.m. on May 6, 2003, Employee #1 was working in the press brake department of a stove manufacturing facility operating a Darley Press Brake, Model Number EHP50 25/20, Serial Number 12508. He was using the press brake to bend a 10-pound piece of 18-gauge sheet metal that was 37 inches long by 18 inches wide with notches on all four sides. While standing in front of the press brake, he held the top of the sheet metal with his left hand and the right side with his right hand. He was wearing white fabric gloves with black rubber dots on them. As he was turning the piece over, his left hand slipped downward and fell sideways to the left. The piece of sheet metal hit his left forearm and made a 4-inch laceration. He was hospitalized for 3 days with his injuries.

Talk to a specialist today

![metal sheet handling unit in use [material handling]](https://www.factorysupply.com/wp-content/uploads/2021/09/img-models-metal-sheet-handling.jpg)

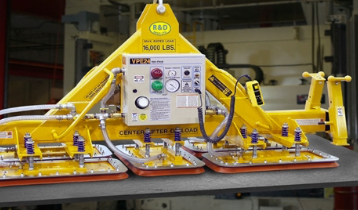

Metal Sheet Handling

Metal sheet handling can be a difficult process or your workforce that can cost excessive time and money. A vacuum sheet lifter can be the perfect addition to your facility to provide a necessary competitive advantage. Utilizing vacuum handling technology is the first step to increasing productivity/efficiency and simultaneously significantly reducing potential workplace injuries.

Glass Sheet Handling

Ensure glass lifting is effortless by removing the strain of manual handling with a reliable and proven Glass Vacuum Lifter. A manually operated vacuum handling system will revolutionize the manufacturing process while reducing lead times and increasing employees’ motivation and performance. Our systems combine to offer functionality, safety and easy ergonomic operation. Designed to be used day in and day out, our ergonomic glass handling systems will increase productivity within your workplace while simultaneously decreasing potential injuries.

![glass sheet handling unit [material handling]](https://www.factorysupply.com/wp-content/uploads/2021/09/img-models-glass-sheet-handling.jpg)

![stone sheet handling unit [material handling]](https://www.factorysupply.com/wp-content/uploads/2021/09/img-models-stone-sheet-handling.jpg)

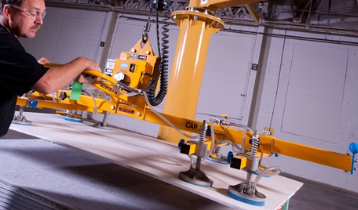

Stone Sheet Handling

We offer production grade, steel framed vacuum lifters for both smooth and/or rough Stone Handling. The systems we build are solid, reliable, and designed to be used on a day-to-day basis. The components we select are durable and reliable, meaning no downtime, and can be relied upon in a variety of environments. Our vacuum lifters offer a secure ergonomic material handling solution for the movement of large slabs and finished stone pieces both within your facility and on-site.

Wood Sheet Handling

Wood Sheet Vacuum Handling Systems are designed for handling rough or smooth wood surfaces, and are designed to lift, tilt, and rotate. Designed to work where you need it, we have both fixed and portable Wood Sheet Vacuum Handling Systems. Our Wood Sheet Vacuum Handling Systems are compact, air-powered and designed for one user to lift heavy wood panels without straps or slings. These systems are ideal for workplaces that require speed for production/assembly, storage, and improved ergonomics.

![wood sheet handling unit [material handling]](https://www.factorysupply.com/wp-content/uploads/2021/09/img-models-wood-sheet-handling.jpg)

Your Perfect Solution Awaits!

KEY FEATURES

Cost-effective solutions

Engineered for performance without compromising your budget.

Safety First

Reduces risk of injuries and Musculoskeletal Disorders (MSDs).

Customized Systems

Tailored solutions designed to fit the unique needs of your workspace.

Workforce productivity

Improves efficiency and output across all workplace operations.

Employee engagement

Boosts satisfaction and involvement by providing safer & convenient equipment.

Compliance

Meets and exceeds all OSHA and ANSI standards for workplace safety.

Cost savings

Minimizes potential fines and lowers insurance premiums through safer practices.

Quality assurance

Enhances the overall quality and consistency of work performed.

PROJECTS

Linen cart mover system

A local hospital commissioned Factory Supply to provide a cart mover system to help safely and efficiently move their linen carts throughout the facility. We provided them with a MasterMover Smart Mover SM100+ with a custom hitch designed specifically for linen carts.

Related Products

Material handling

Ergonomic material handling solutions engineered for safety, productivity, and lasting workplace efficiency.

NETTING SAFETY Systems

Our netting systems have been designed to meet all required safety measures to reduce injuries and liability.

Rooftop Safety

Products

Reliable rooftop safety solutions designed for compliance and protection.