Bag Handling Equipment

Repetitive movements through bag handling can often lead to employee injury and downtime. Reducing this impact will not only improve performance but also employee morale.

One option for eliminating employee injury is to implement a vacuum bag handling solution. Vacuum Lifters are the perfect solution for quickly and safely moving sacks and bags efficiently and safely, without harming the product. Our products can be completely customized to suit your specific application, space and budgetary constraints. We have experience engineering, designing, installing and training on systems such as:

- Permanent fixed vacuum bag handling systems

- Portable bag handling systems

- Multi-lift bag handling systems (for more than one bag/sack at a time)

Reducing Lifting Exposures

Cal/OSHA’s regulation, 5110, details three control methods for reducing repetitive motion injuries.

- Engineering controls

- Administrative controls

- Training

Vacuum lifter VT Model (Anver VT)

This VT system can be adjusted to match the operator(s) hand strength and provides a 100% continuous duty cycle. This system features a bag handling pad attachment, designed to move product on pallets and conveyors without bending, stretching, reaching, or lifting.

The VT boasts an easy-to-use up and down control system with an easy-grip handle. Baghead attachments are available in plastic and stainless steel depending on the nature of the industry and includes a heavy-duty pump, wire-reinforced tube, and vacuum gauge.

Vacuum Lifter M Model (Easyhand M)

Easyhand M is a modular vacuum lifter that can handle loads up to 110 pounds. It makes bag handling simple and convenient, and owing to a vast selection of standardised grippers and attachments, such as swivels, angle joints, quick release mechanisms, and extended and articulated handles, the lifter may be customised to meet your specific demands. An ergonomically constructed control handle controls the raising and lowering operation. With or without a load, the lifter’s stand-by height can be easily adjusted using controls on the operating handle.

Vacuum Lifter Pro Model (Vacuhand Pro)

The Vacuhand Pro is a powerful vacuum lifter that can raise up to 550 pounds. The lifter is controlled by a handle for two-handed operation and allows for easy and effective sack and bag handling. Because of the lifter’s high capacity and versatility, Vacuhand Pro is an obvious choice for handling sacks. Vacuhand Pro offers a diverse product line that includes a variety of lifting unit models, power sources, and accessories, as well as grippers and special suction cups for lifting objects of various sizes and materials.

This vacuum features adjustable stand-by positions for both with and without loads, as well as smooth and operator-friendly material handling. To fit each workplace, the controller can be equipped with an articulating or fixed handle of various lengths.

Vacuum Lifter Pro Model (Easyhand Pro)

Easyhand Pro is a modular vacuum lifter that can handle loads up to 110 pounds. It makes handling everything from sacks and cardboard boxes to sheet materials like glass and sheet metal much easier and more convenient. With a wide choice of standardised grippers and attachments, such as swivels, angle joints, and quick connections, this ergonomic lifter may be simply customised to meet your specific demands. An ergonomically constructed control handle controls the raising and lowering operation. With or without a load, the lifter’s stand-by height can be easily adjusted using controls on the operating handle.

Models

- Drastic reduction in heavy/repetitive lifting

- Customized for your specific application, designed to work with your product(s)

- Reduction in workplace illness/injury claims, resulting in lower insurance costs

- Allows for diversity/adaptability on the job, more workers are now able to complete the task without physical limitations being an issue

- Our systems pay for themselves via productivity and efficiency increases

- Weight and capacity ranges are considered during the design process, our systems can handle multiple weights, textures and products without altering the system

- Designed to work in your specific facilities conditions, such as high heat, dust, humidity, moisture etc.

- Automotive

- Manufacturing

- Pharmaceutical

- Hospital Food & Beverage

- Warehouse

- Retail

All of our Vacuum Handling solutions either meet or exceed all applicable regulations which include; OSHA, ANSI and ASME B30.20.

- Anver

- Easyhand

- Vacuhand

- Plastic or Paper Bags and Sacks

- Burlap Bags and Sacks

- Polywoven Bags and Sacks

Your Perfect Solution Awaits!

Ergonomic Material Handling

Cost effective material handling solutions

Custom engineer systems

Meets or exceeds all OSHA and ANSI safety standards and regulations

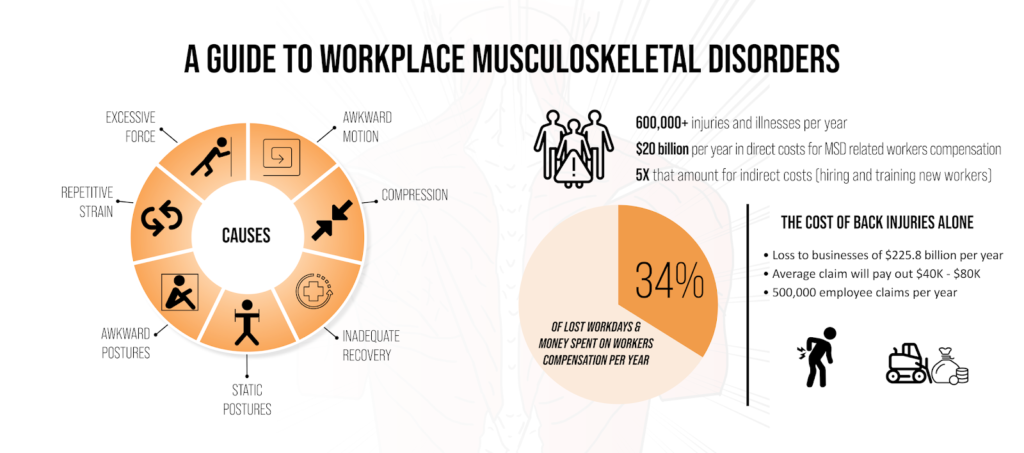

Protect employees from workplace injuries and Musculoskeletal Disorders (MSDs)

Reduces the potential for costly fines and high insurance premiums

Improved productivity of workforce

Improved quality of work

Increase employee engagement and satisfaction

Related Products

Tote and Box Handling Equipment

Factory Supply has an extensive line of Ergonomic Box and Tote Handling Equipment designed to improve efficiency and eliminate workplace injuries. We have both portable and fixed systems.

Sheet Handling Equipment

Lifting sheets safely is often a challenging material handling problem. We offer a variety of vacuum sheet handling solutions designed in order to safely lift and move sheets made of a variety of materials.

Odd Shapes and Custom Material Handling

The engineering team at Factory Supply can fabricate or assemble custom products with standard parts that can lift, angle, rotate and move irregular products while causing no damage to the product.

About Factory Supply

Projects

See if we have already solved the

problem you are having by viewing

the latest projects delivered by

Factory Supply.