Forklift Roll Handling Attachments

Many facilities already have forklifts that perform other functions within it and all they require to upgrade their roll handling is an attachment that upgrades their already existing equipment.

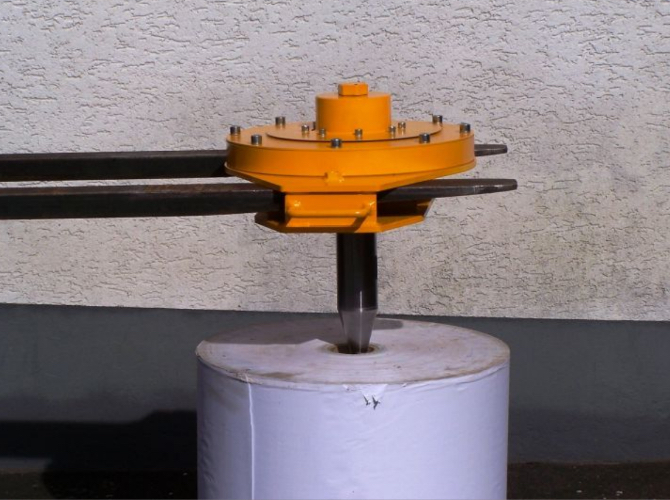

Various forklift attachments can be used to safely perform different functions while handling rolls. These forklift roll handling attachments are inserted into the core of the roll and allow for automatic switches from gripping and releasing, enabling the user to quickly and efficiently move rolls throughout their facility.

Utilize your already existing technology with this roll handling forklift attachment which will enable you to pick up and move rolls with your already existing equipment. This forklift roll handling attachment is inserted into the core of the roll and allows for automatic switches from gripping and releasing, enabling the user to quickly and efficiently move rolls throughout the roll handling unit.

- Drastic reduction in heavy/repetitive lifting

- Customized for your specific application, designed to work with your product(s)

- Reduction in workplace illness/injury claims, resulting in lower insurance costs

- Allows for diversity/adaptability on the job, more workers are now able to complete the task without physical limitations being an issue

- Our systems pay for themselves via productivity and efficiency increases

- Weight and capacity ranges are considered during the design process, our systems can handle multiple weights, textures and products without altering the system

- Designed to work in your specific facilities conditions, such as high heat, dust, humidity, moisture etc.

- Pulp and Paper

- Textile

- Packaging

- Pharmaceutical / Medical

- Food and Beverage

- Manufacturing

All of our Material Handling solutions either meet or exceed all applicable regulations which include; OSHA, ANSI and ASME B30.20.

Injury incident: Accident Report Detail

At 9:00 a.m. on November 10, 2018, an employee was using a hoist to lift a 12 inch wide roll of paper on a pallet and the hoist shaft came out of the roll. The employee fractured his ankle and leg when the roll tilted off the pallet and struck him. The employee also sustained soft tissue damage to his leg and ankle as well. The employee was hospitalized.

Talk to a specialist today

KEY FEATURES

Cost-effective solutions

Engineered for performance without compromising your budget.

Safety First

Reduces risk of injuries and Musculoskeletal Disorders (MSDs).

Customized Systems

Tailored solutions designed to fit the unique needs of your workspace.

Workforce productivity

Improves efficiency and output across all workplace operations.

Employee engagement

Boosts satisfaction and involvement by providing safer & convenient equipment.

Compliance

Meets and exceeds all OSHA and ANSI standards for workplace safety.

Cost savings

Minimizes potential fines and lowers insurance premiums through safer practices.

Quality assurance

Enhances the overall quality and consistency of work performed.

Your Perfect Solution Awaits!

PROJECTS

Linen cart mover system

A local hospital commissioned Factory Supply to provide a cart mover system to help safely and efficiently move their linen carts throughout the facility. We provided them with a MasterMover Smart Mover SM100+ with a custom hitch designed specifically for linen carts.

Related Products

Material handling

Ergonomic material handling solutions engineered for safety, productivity, and lasting workplace efficiency.

NETTING SAFETY Systems

Our netting systems have been designed to meet all required safety measures to reduce injuries and liability.

Rooftop Safety

Products

Reliable rooftop safety solutions designed for compliance and protection.