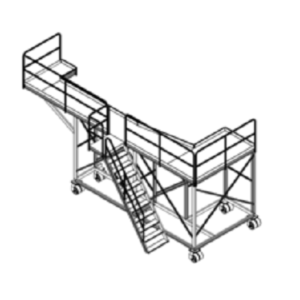

Engine Access Stands

Sturdy, adjustable, fully mobile stands that provide safe access to hard-to-reach areas.

Factory Supply designs and manufactures aircraft maintenance stands for both under and over cowling access, accommodating a wide range of aircraft types. These stands provide safe and efficient access to maintenance inspection points for painting, assembly, overhaul, and repair operations.

Each engine access stand is engineered for safety, comfort, and functionality. Our designs include anti-fatigue ladder steps—not narrow rungs—to ensure operator comfort during tasks such as changing LRUs, adjusting components, or connecting and disconnecting engines and nacelles. With a lightweight design, compact footprint, and optimized geometry, these stands enhance maneuverability and usability.

Currently trusted by operators, MROs, and aircraft manufacturers across North America, Factory Supply’s maintenance stands are built with premium American materials and exceed all OSHA and ANSI regulatory standards.

From concept through design, fabrication, and installation, Factory Supply specializes in both standard and custom fixed-wing engine access stands. Working with clients in the Commercial, Military, and Private aviation sectors, we have earned recognition for innovation, dependability, and quality service—helping maintenance teams work safely, efficiently, and confidently while protecting their aircraft.

Our defining philosophy, “safety in the air starts on the ground,” highlights our core focus of keeping our clients and their teams safe.

All Factory Supply products are engineered, designed, built and tested in accordance with OSHA and ANSI regulations.

Many of our products have also been tested and meet or exceed BS EN 131.7, DIN EN 12312-8, EN 1915-1 and include CE certifications.

Lightweight and multi-fuctional design, capable of providing a safe solution in a range of applications. Easily access maintenance and inspection points, and hard to reach panels and under-wing areas.

Heavy duty aluminum construction with anti-slip, anti-fatigue ladder steps for easy movement and corrosion-resistant powder coat finish for longevity.

KEY FEATURES

In-house expertise

We are well-equipped and ready to tackle your custom projects.

Safety First

All our products are designed and built in accordance with industry standards.

Custom design

Custom access products and equipment designed with advanced software.

Innovation

Developed with advanced design software and streamlined processes.

Compliance

Meets and exceeds compliance standards, including ANSI, OSHA and Cal/OSHA.

Customer service

We provide the best experience while meeting and exceeding project expectations

Talk to a specialist today

KC135 Engine Maintenance Stand

Compatible Aircraft:

Boeing

See full list

Gulfstream Engine

Maintenance Stand

Compatible Aircraft:

Gulfstream

See full list

![Adjustable engine access stand [DF071554 07 10]](https://www.factorysupply.com/wp-content/uploads/2021/09/DF071554-07-10-300-dpi-300x300.png)

Engine Access Stand

DF071554-06

For:

Outboard Engines

See full details

![Engine Access Stand [adjustable]](https://www.factorysupply.com/wp-content/uploads/2021/09/img-DF071554-07-08-R2-300x300.png)

Engine Access Stand

DF071554-07-08

For:

Over and Under Cowling

See full details

Engine Access Stand

DF071554-07-10

For:

LRU Change, Connect/Disconnect Engines & Nacelles

See full details

Engine Access Stand

DF071554-07-12

For:

LRU Change, Connect/Disconnect Engines & Nacelles

See full details

side scroll stands

Compatible Aircraft:

Airbus, Boeing

See full list

Factory Supply Aviation Access Equipment has been engineered to fit multiple aircraft types and access points. Please note that in addition to the aircraft models listed, our equipment meets the criteria of numerous aircraft models that match the access point specifications of our tested equipment. Contact our specialists to confirm if your aircraft is applicable or for customization options.

Trusted by +2000 businesses

DOWNLOADS

| Document | Format | Link |

|---|---|---|

| Heli Grade Solutions Catalogue | Download | |

| Aircraft Access Stand Specification Sheet | Download | |

| Aircraft Maintenance and Engine Access Stand Specification Sheet | Download | |

| Aviation Wheel Well and Platform Stand Specification Sheet | Download | |

| Cabin Interior Access Stand Specification Sheet | Download | |

| Engine Access Slide Scroll Stands Specification Sheet | Download | |

| Landing Gear Change Stand Specification Sheet | Download | |

| Maintenance Platforms and Docking System Specification Sheet | Download | |

| Nose Cowl Dolly Specification Sheet | Download | |

| Wheel and Brake Service Carts (Tire Trailers) Specification Sheet | Download |

Regulations & Certifications

| OSHA |

| ANSI |

| BS EN 131.7 |

| CE |

| DIN EN 12312-8 |

| EN 1915-1 |

Your Perfect Solution Awaits!

Our process

At Liftsafe, we are focused on collaboration and innovation. Whether you need a custom designed solution, or are simply looking for an “out of the box” product, our process remains laser focused on exceptional service and support.

Phase 1: Design

Every project is unique. In this phase, we take a collaborative and consultative approach to define requirements, evaluate your needs, and explore all possible solutions to ensure the right fit for your operation.

Phase 2: Safety

Our defining philosophy—“safety in the air starts on the ground”—drives our focus on keeping your teams protected. Every solution we develop prioritizes hazard elimination and integrates passive safety features into each design.

Phase 3: Compliance

The aviation sector is one of the most heavily regulated industries in the world. Our staff engineers are up to date on the latest safety regulations and ensure that each piece of equipment meets or exceeds safety compliance standards.

Phase 4: Implement

Each project is launched through a structured process that includes manufacturing, commissioning, and training. Every solution is tested under real-world conditions and refined to meet all design criteria for safe, reliable performance.

Phase 5: Support

Once an aircraft maintenance platform is in service, it faces real-world conditions. That’s why Liftsafe provides ongoing preventative maintenance and service plans to ensure reliable operation and ongoing customer support.

Safety Solutions for Aircraft Maintenance

Factory Supply combines the technical expertise of our aviation specialists and in-house engineers with your team to turn your vision and requirements into high-quality, safe, and reliable aircraft access stands. We work collaboratively with you throughout the engineering, design, fabrication, and testing phases to deliver products that exceed your expectations and all regulatory requirements.

Ongoing research and alignment with industry trends, customer needs, market conditions, and technological advancements remain central to our innovative approach.

Our goal is not only to create safe and reliable products, but also to identify opportunities to improve the way you maintain your facility and aircraft.

PROJECTS

C37 And G550 Tail Dock

Providing complete access to critical components of the aircraft, this Tail Dock Stand provides both vertical and horizontal access to the tail of the aircraft. Heavy duty construction of the access stand ensures it will stand up to substantial usage.

Boeing 757 Aircraft Wing Stand

Safety is paramount in the aviation industry, hence the necessity for consistent maintenance of aircraft while also ensuring the safety of maintenance crew. Investing in high-quality maintenance stands makes good business sense.

C-130 Trainer Access Platform

Our latest customer required a personalized solution for their state of the art training facility. The C-130 trainer access platform was designed, supplied and installed by the Liftsafe Engineering team. The project was completed before deadline and under budget.

Related Products

Crew Access Stands

Designed for safe, efficient cockpit and main deck access during hangar, ramp, and line maintenance.

Landing Gear Stands

Landing gear stands with anti-fatigue steps and versatile design for safe, comfortable aircraft maintenance.

Wheel Well Access

Stands & Ladders

Ergonomic stands with anti-fatigue steps designed to provide safe, comfortable access for wheel well maintenance.