Portable Truck Netting Systems

Falls from flatbed trucks during loading and unloading continue to increase, often due to irregular materials like steel, timber, or pipe, unbalanced loads, and limited awareness of fall protection safety requirements across the industry.

Our Portable Truck Net Systems provide a flexible safety solution for facilities that prefer not to pour footings or permanently anchor posts in place. Originally developed for outdoor use as tarping or load securement stations, these systems can be installed anywhere with a flat, level surface.

Each unit is fully relocatable—if you need to move the system months later, a standard forklift can easily reposition it using the built-in fork pockets. Bases are delivered empty, with rebar and anchors welded in place; once on-site, simply fill with concrete to reach the required ballast weight for stability and compliance.

Our netting panels are treated to meet NFPA 701 standards for fire-retardancy and have been tested and rated in accordance with ANSI A10.11 and OSHA safety standards. This includes the complete system with all of the hardware installed onto a racking system and tests made to simulate a real-case product falls.

To ensure compliance with regulations, we advise following safety net installation standards. This includes obtaining certification from qualified installers or engineers, conducting testing procedures, maintaining thorough records, and providing worker training.

A comprehensive fall protection plan must consider work nature, site or facility conditions, load capacity, and manufacturer specifications. Proper installation, maintenance, and regular inspection are critical for compliance and effectiveness.

Accumulated debris can compromise the functionality of safety nets and create hazards. Work operations should pause promptly to remove debris or any fallen objects to maintain optimal net performance.

KEY FEATURES

Tailored Solutions

Customized netting systems designed to fit your facility and workflow needs

Employee Protection

Provides reliable protection to prevent injury or death from falling objects.

COST-EFFECTIVE

Efficient and affordable solutions that reduce costs while improving safety.

Risk Reduction

Helps minimize potential fines, insurance claims, and costly incidents.

Compliance

Exceeds compliance standards, including ANSI, OSHA and Cal/OSHA.

Safety First

Products engineered with uncompromising safety and quality to protect your people.

Public Protection

Protects passersby and visitors from injury caused by falling materials.

Durable Design

Constructed for long-lasting use, ensuring ongoing safety and peace of mind.

Talk to a specialist today

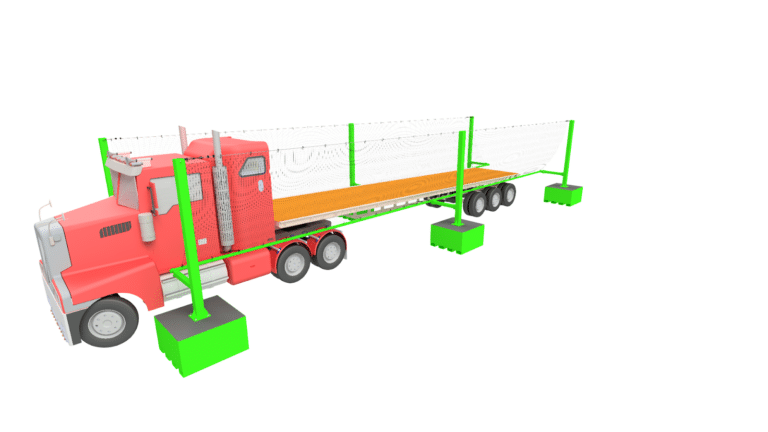

Pivoting Portable Truck Netting System

The Pivoting Portable Truck Netting System features a compression arm that pivots to rest directly against the flatbed truck, creating a quick and reliable fall protection solution. This system is ideal for facilities with multiple-use bays or for customers who prefer not to connect directly to the flatbed.

The compression arms swing out from the columns and position against the side of the flatbed, providing protection that is fast and easy to set up. Each system is engineered with non-permanent weighted bases and fixed columns that can be relocated as needed. The bases include fork pocket holes for effortless repositioning and are commonly used in areas where mounting posts are not feasible. All components can be easily disassembled for transport or reconfiguration.

- 3 columns (6-inch x 6-inch)

- Pivoting arm

- Compression bar (made up of three bars)

- Column base (4 ft x 4 ft x 2.5 ft)

- 3/8-inch galvanized GAC

- Snap hooks for every 2 ft

- 2 3/8-inch light duty thimble

- 1 net panel

- 4 3/8-inch wire rope clips

- 1 TB (6-inch x half inch)

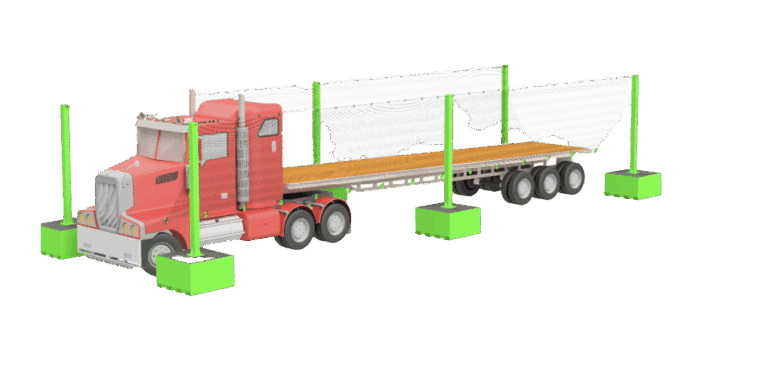

Fixed Base Portable Truck Netting System

The Fixed Base Portable Truck Netting System features weighted bases with fixed vertical columns that can be easily relocated and used in multiple areas throughout your facility. Designed for outdoor applications, this non-permanent safety system eliminates pavement mounting challenges with fork pocket bases that allow for quick repositioning.

The netting attaches securely using wire rope and custom brackets that connect to the stake pockets of flatbed trailers, providing dependable fall protection during loading and unloading. This system is ideal for applications where pouring concrete footings or installing permanent posts isn’t possible.

Compact, durable, and easy to move, the Fixed Base Portable Truck Netting System helps protect employees from falls while taking up minimal space in your facility.

- 3 columns (6-inch x 6-inch)

- Column base (4 ft x 4 ft x 2.5 ft)

- 3/8-inch galvanized GAC

- Snap hooks for every 2 ft

- 2 3/8-inch light duty thimble

- 1 net panel

- 4 3/8-inch wire rope clips

- 1 TB (6-inch x half inch)

Your Perfect Solution Awaits!

Netting Specifications

| Specification | Details |

|---|---|

| Product Name | Truck Safety Netting |

| Manufacturer | Factory Supply |

| Safety Standards Compliance |

OSHA MOL ANSI WorkSafeBC OBC NBC CSA BS EN CE Certification |

| Netting Panel |

3000 lbs net – 2” square, industrial safety netting |

| Netting Colour |

Black Yellow Custom colours are available for large orders |

| Netting Material |

3000 lbs net – nylon |

| Netting Cable | 1/4” aircraft cable |

| Netting Design |

Knotless netting Sewn rope border U.V. protection |

| Rigging Components |

Columns Pivoting arm Compression bar Column base Galvanized GAC Snap hooks Thimble Net panels Wire rope clips |

| Bases | 4000 lbs (2 tons per base) |

FREQUENTLY ASKED QUESTIONS

Passive vs Active fall protection?

Passive fall protection does NOT require any action by people. Examples include: Guardrails, Safety Nets, etc. Active fall protection requires training and direct connection to an engineered fall protection system or anchor point. Examples include: Body Harnesses and Lanyards, Anchor Points, etc.

What are the regulations i need to know?

OSHA 12.10 (1.1), every employer shall provide a fall-protection system to any person, other than an employee who is installing or removing a fall-protection system in accordance with the instructions referred to in subsection (5), who works: (a) from an unguarded structure or on a vehicle, at a height of more than 2.4 m above the nearest permanent safe level; (b) from a temporary structure at a height of more than 6 m above a permanent safe level.

ANSI A10.11 All nets supplied are manufactured and tested in accordance with Industry Standards, and all such netting has been tested to strict ANSI standards as laid out in ANSI A10.11. This includes the complete system with all hardware installed onto a racking system and tests made to simulate a real-case product fall.

Is this something I could install on my own?

Yes, all of our systems include a user manual, custom drawing, and detailed installation instructions. If needed, we offer installation services.

Untested and/or self-fabricated remedies are risky. You are responsible for any accidents relating to the failure of hardware and installation. Incorrect installation could result in a system that does not provide the protection you require.

When would I need truck netting?

Netting is used anytime a fall hazard may exist. It is used to protect workers when performing a job on or around a parked flatbed truck.

What do I need to provide to get a quote?

Get in touch with our netting sales reps, and they can provide you with a Quote Request Form that is easy to fill out. The form asks for information such as the width of your bays, the height of your rack frames, and the weight of the pallets you are looking to protect.

Things to consider

The amount of space available beside the “typical” trailer location when loading/tarping/etc.

The further away from the trailer you can position the posts, the lower the posts have to be.

Overhead cranes. Do they load from the side, the end or both? If from the side, how high can the posts be without interfering with the loading process?

Connection to the trailer – the standard system requires attachment directly to the trailer while the pivot system does not.

Forklift loading from the side – is this done at all? If so, the trailer safety nets will not work.

PROJECTS

![engineered truck netting system [fall protection]](https://www.factorysupply.com/wp-content/uploads/2021/09/716-300x225.jpg)

4 permanent truck net systems installed

To resolve a fall protection concern, four permanent Truck Netting Systems were installed to ensure staff safety during day-to-day operations.

![engineered pivoting truck netting system [fall protection]](https://www.factorysupply.com/wp-content/uploads/2021/09/377-1-1-300x225.jpg)

Pivoting truck net system

Our Memphis Pivoting Net System was a Custom Truck Net application designed to keep both product and people safe.

![engineered portable truck netting system [fall protection]](https://www.factorysupply.com/wp-content/uploads/2021/09/657-1-1-300x220.png)

Portable truck net system

Responding to an immediate fall protection concern, Factory Supply shipped three Portable Truck Net Systems to this corporation. The feedback from the customer was phenomenal as it immediately addressed and resolved their fall protection concerns.

![Warehouse rack netting solution install [rackguard]](https://www.factorysupply.com/wp-content/uploads/2021/09/870-300x225.jpg)

Warehouse netting solution install

Having been the industry leader for rack protection for many years, Warehouse Netting can be applied in a variety of circumstances. Even when shelving units are of varying sizes and the configuration may be odd, custom solutions can be created, ensuring the protection of your goods and equipment while keeping your people safe.

RELATED PRODUCTS

Column Mounted Truck Netting Systems

Our column mounted truck net systems provide compact, reliable fall protection for workers in multi-bay facilities.

Wall Mounted Truck

Netting Systems

Our wall mounted truck nets protect workers from open bay gaps in confined or recessed loading areas.

NETTING SAFETY

Systems

Our netting systems have been designed to meet all required safety measures to reduce injuries and liability.