Gargoyle Rooftop Guardrail

The Gargoyle Rooftop Guardrail system is designed to protect the most common working at heights hazard, a rooftop or any other exposed edge. Distance from the edge of an elevated surface is the key factor when it comes to this type of hazard. According to OSHA regulations, fall protection must be provided at elevations of four feet in general industry workplaces, five feet in shipyards, six feet in the construction industry and eight feet in longshoring operations. Some scenarios have a lower height requirement (above dangerous machinery, hazardous materials, etc.) details on this is made available publicly by OSHA.

What is Gargoyle Rooftop Guardrail?

The Gargoyle Rooftop Guardrail system is a modular, non-penetrating system, designed to eliminate the potential hazard of falls over unprotected edges on a rooftop or elevated surface. With simplicity in mind when developed, this rooftop guardrail system can be quickly and easily assembled and installed on most rooftops. Because Gargoyle is counter weighted, it requires no welding, drilling, or bolting into the actual roof structure and is designed to rest on top of it while still meeting lateral force requirements set out in the appropriate standards and laws. Gargoyle can be reconfigured during installation in order to allow it to work in almost any situation. Our Professional Engineers or fall protection specialists can consult with you on your jobs to ensure that you have the proper design for your rooftop. Gargoyle has been designed to meet or exceed all American safety requirements, including OSHA (Construction and Industrial Activities), and expanded working at heights laws in Washington, Oregon, Michigan, Kentucky and California.

Your Perfect Solution Awaits!

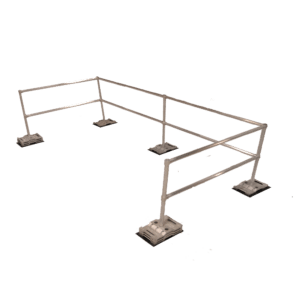

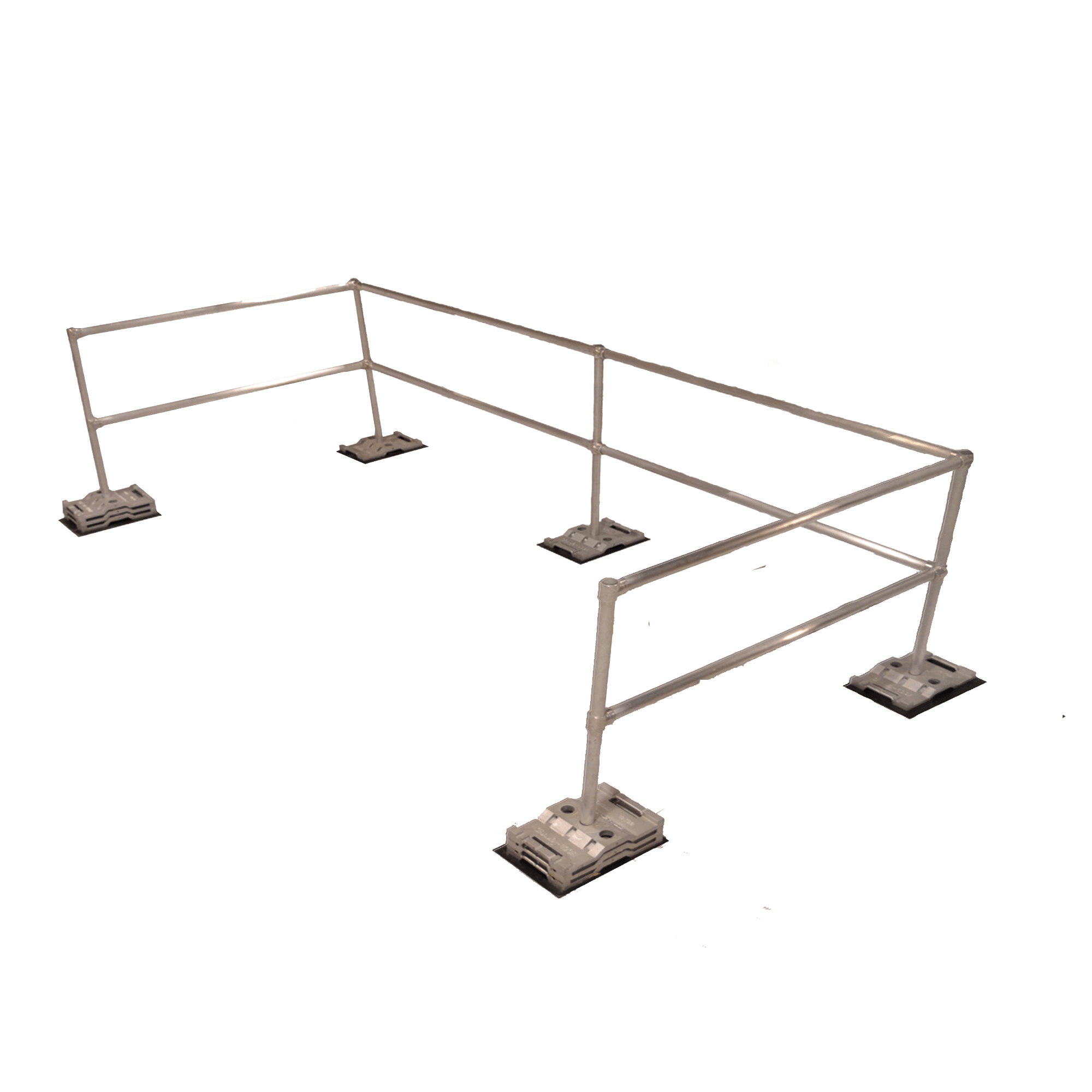

9 foot Kit | Gargoyle Edge Protection

Rooftop Guardrail with nine feet of leading edge Fall Protection. It sits on top of the roof membrane, and is a passive fall protection solution. The nine foot standard kit is ideal for providing reliable fall protection around HVAC units, vents, near access ladders, antennas, valves, solar panels, or simply near frequently travelled areas that require routine maintenance.

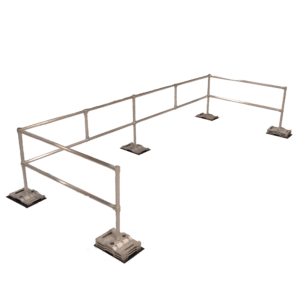

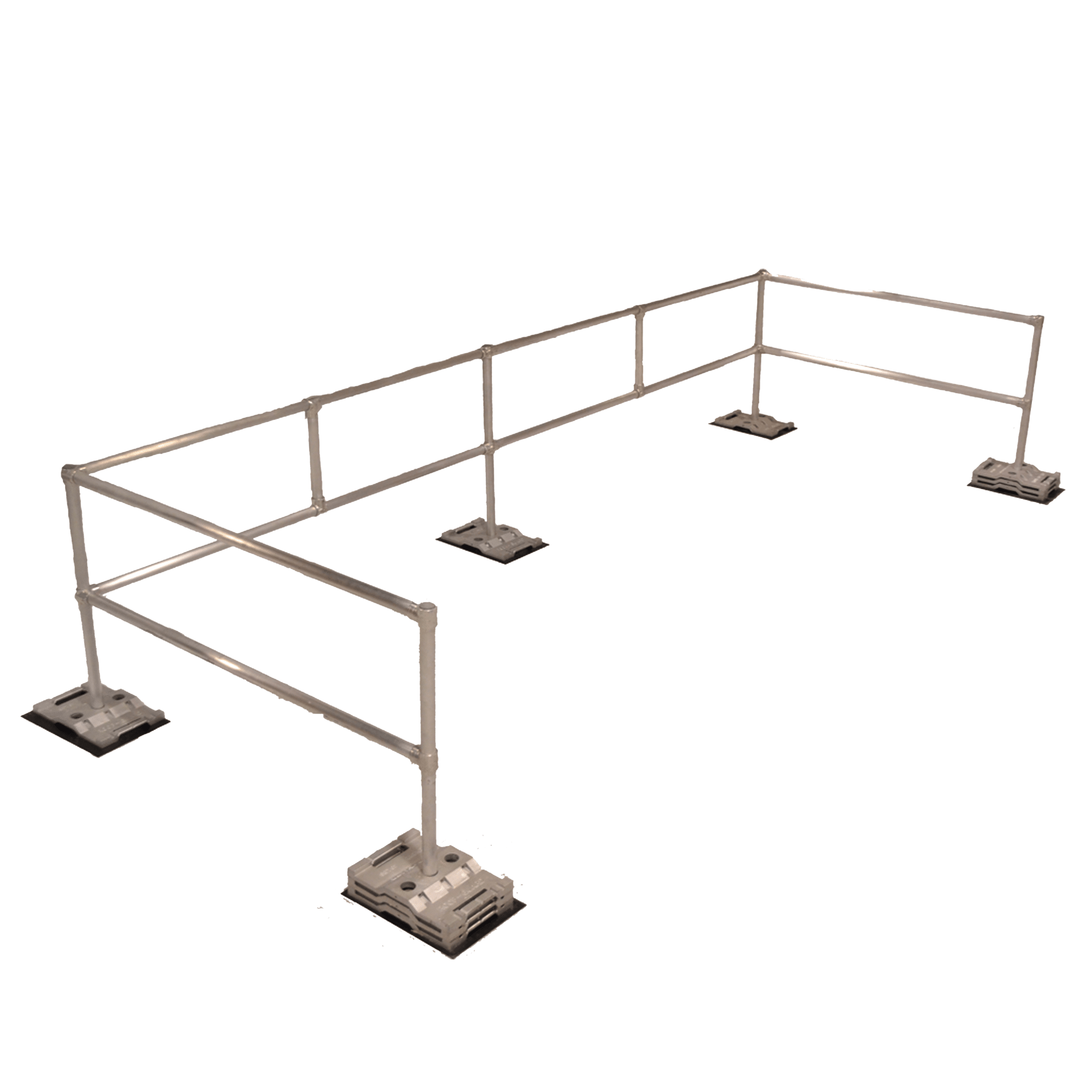

12 Foot Kit | Gargoyle Edge Protection

Twelve feet of leading edge Fall Protection. The Gargoyle 12 foot kit is ideal for providing reliable fall protection around HVAC units, vents, near access ladders, antennas, valves, solar panels, or near exposed areas that require routine maintenance.

This system is equipped with a variable fitting in the centre to allow for straight or 90 degree setup, two 6′ returns (ballast), aluminum handrail tube, cast aluminum magnesium fittings, base plates, rubber pads and an installation tool.

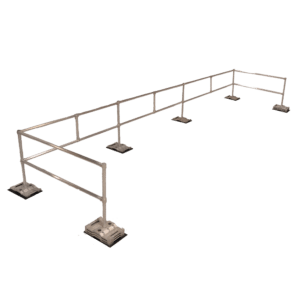

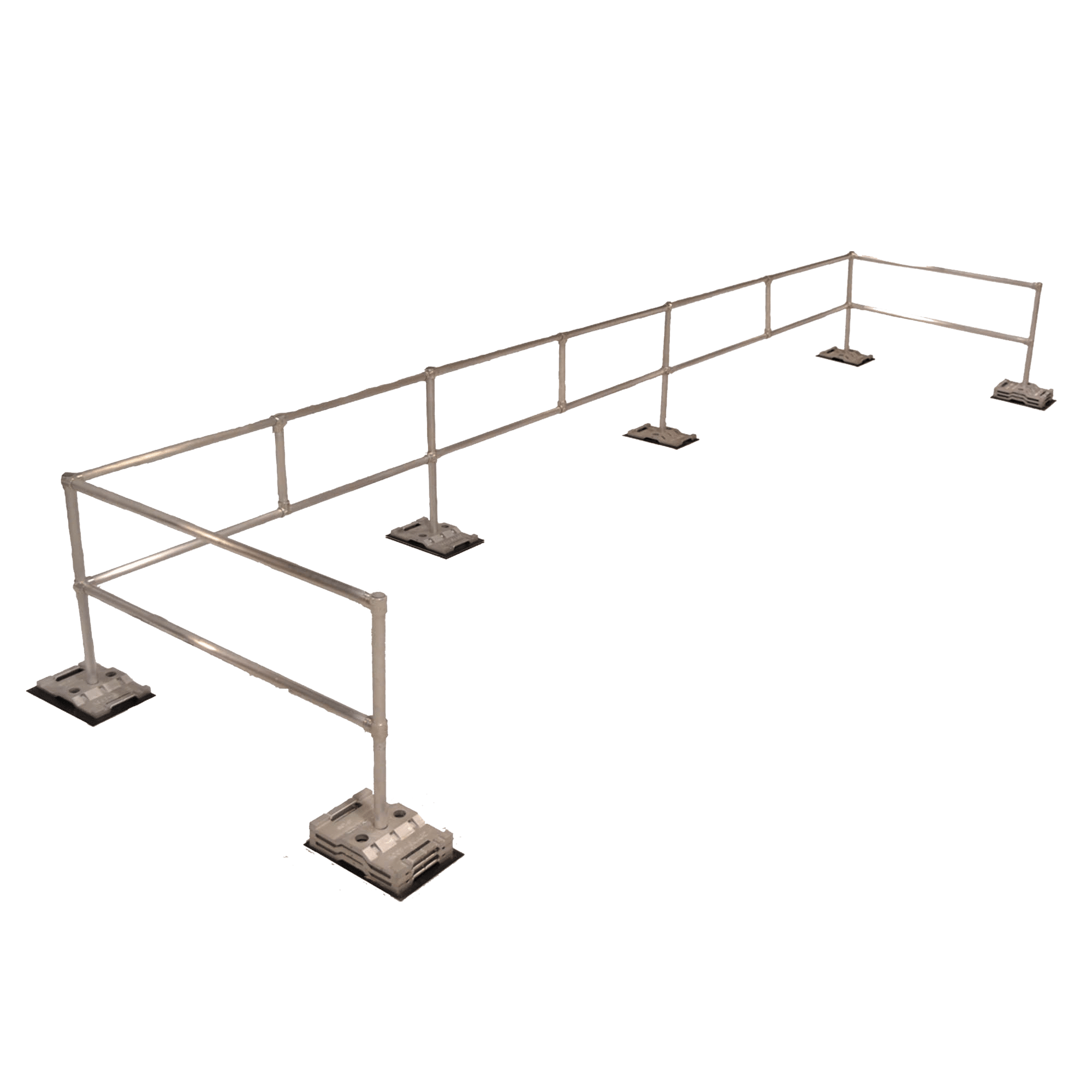

18 foot Kit | Gargoyle Edge Protection

Our most popular rooftop guardrail design offers eighteen feet of leading edge Fall Protection, with two six foot sections for weighted ballast. The hinged, variable fitting in the centre of the 18 ‘ section allows for complete versatility when installing the system. It can be straight, at 90 degrees or anything in between.

The best way to ensure the safety of your workers is to plan ahead and implement a fall prevention solution within the areas of your rooftop that require access. Custom configurations available depending on your unique application.

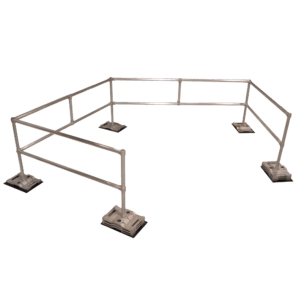

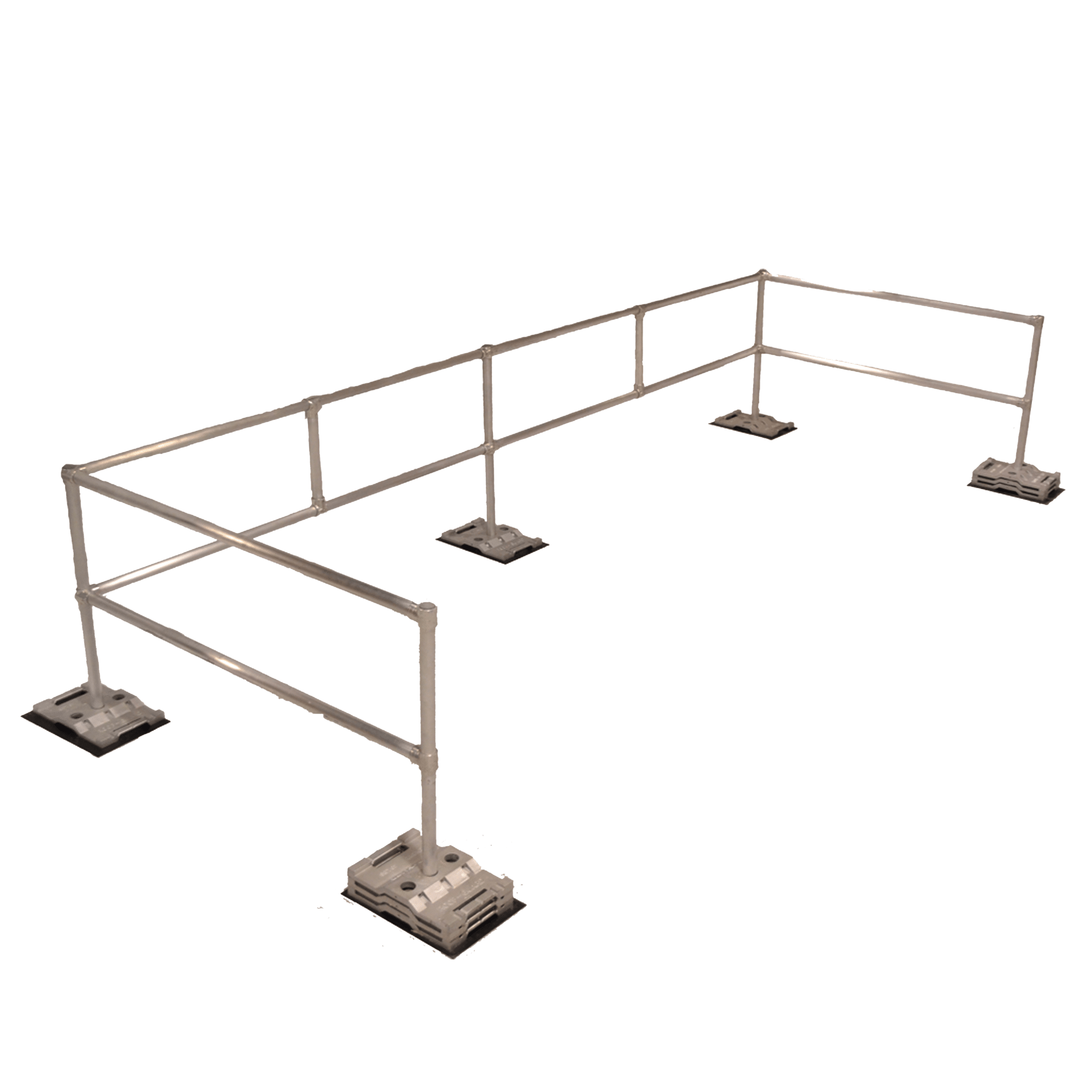

27 Foot Kit | Gargoyle Edge Protection

Twenty-seven feet of leading edge Fall Protection with two six foot sections for weighted ballast. Two hinged fittings allow for complete versatility when installing the system. It can be straight, at 90 degrees, or anything in between, depending on your requirements.

Our largest Gargoyle Rooftop Guardrail System and it is designed to allow for the maximum amount of both linear coverage and flexibility, ensuring that your employees or contractors are protected around a wide variety of different potentially dangerous situations on your rooftop. These are typically used for edges that have multiple units that are unprotected in a row.

Custom | Gargoyle Edge Protection

Our custom kits are designed for multiple application purposes so that you have a readily available system to ensure that your rooftop is safe. For applications that require something unique, we have our custom rooftop guardrail system because everyone should be able to work safely and with confidence, whether they are in an office or on a rooftop.

These rooftop guardrail systems were designed with one thing in mind, to have a rooftop guardrail system available for everyone, because safety should never take a back seat.

Gargoyle Rooftop Guardrail Specifications

| Kit Size | Part Number | Height | Coverage | Diameter of Rail | Unit Weight |

|---|---|---|---|---|---|

| 9 feet | RGC-KIT-09 | 42" from the ground to the top of the top rail | 9 linear feet of coverage | 1.9" OD Aluminum Pipe | 450 lbs. |

| 12 feet | RGC-KIT-12 | 42" from the ground to the top of the top rail | 12 linear feet of coverage | 1.9" OD Aluminum Pipe | 500 lbs. |

| 18 feet | RGC-KIT-18V | 42" from the ground to the top of the top rail | 18 linear feet of coverage | 1.9" OD Aluminum Pipe | 525 lbs. |

| 27 feet | RGC-KIT-27V | 42" from the ground to the top of the top rail | 27 linear feet of coverage | 1.9" OD Aluminum Pipe | 600 lbs. |

OSHA Working at Heights Laws

| Jurisdiction | Regulation |

|---|---|

| OSHA (Construction Activities) |

|

| OSHA (Industrial Activities) |

|

| Washington State Department of Labor and Industries | Chapter 296-880 WAC Unified Safety Standards for Fall Protection |

| Oregon OSHA |

|

| Michigan MIOSHA | Construction Standard Part 45, Fall Protection |

| Kentucky KY OSH | State Specific Regulations Applicable to Construction 803 KAR 2:412, Fall Protection |

| California CalOSHA | California Code of Regulations, Title 8, Section 3210, Guardrails at Elevated Locations |

Resources

10 Common Rooftop Safety Hazards

The top 10 common hazards to note before stepping onto a rooftop.

New US Rooftop Safety Standards

Breaking down the new US rooftop safety standards and how to stay compliant.

Gargoyle Rooftop Guardrail Kit

27' Gargoyle system is being used as edge protection around a rooftop HVAC unit.

Frequently Asked Questions

Is Gargoyle required by law?

Guardrails are one form of fall protection that can be used as a requirement for working at heights. It is preferrable when it can be used because it is a passive system. The federal laws that apply to working at heights are:

OSHA 1926 Subpart M: Fall Protection – 1926.501(b)(2)(ii)

Each employee on a walking/working surface 6 feet (1.8 m) or more above a lower level where leading edges are under construction, but who is not engaged in the leading edge work, shall be protected from falling by a guardrail system, safety net system, or personal fall arrest system. If a guardrail system is chosen to provide fall protection, and a controlled access zone has already been established for leading edge work, the control line may be used in lieu of a guardrail along the edge that parallels the leading edge.

OSHA 1926 Subpart M: Fall Protection – 1926.501(b)(4)(i)

Each employee on walking/working surfaces shall be protected from falling through holes (including skylights) more than 6 feet (1.8 m) above lower levels, by personal fall arrest systems, covers, or guardrail systems erected around such holes.

OSHA 1910 Subpart D – Walking-Working Surfaces – 1910.28(b)(1)(i)

Except as provided elsewhere in this section, the employer must ensure that each employee on a walking-working surface with an unprotected side or edge that is 4 feet (1.2 m) or more above a lower level is protected from falling by one or more of the following: 1910.28(b)(1)(i)(A) – Guardrail systems; 1910.28(b)(1)(i)(B) – Safety net systems; or 1910.28(b)(1)(i)(C) – Personal fall protection systems, such as personal fall arrest, travel restraint, or positioning systems.

OSHA 1910 Subpart D – Walking-Working Surfaces – 1910.28(b)(7)

Openings. The employer must ensure that each employee on a walking-working surface near an opening, including one with a chute attached, where the inside bottom edge of the opening is less than 39 inches (99 cm) above that walking-working surface and the outside bottom edge of the opening is 4 feet (1.2 m) or more above a lower level is protected from falling by the use of: 1910.28(b)(7)(i) – Guardrail systems; 1910.28(b)(7)(ii) – Safety net systems; 1910.28(b)(7)(iii) – Travel restraint systems; or, 1910.28(b)(7)(iv) – Personal fall arrest systems.

At what height is fall protection required by law?

According to OSHA:

Employers must set up the work place to prevent employees from falling off of overhead platforms, elevated work stations or into holes in the floor and walls. OSHA requires that fall protection be provided at elevations of four feet in general industry workplaces, five feet in shipyards, six feet in the construction industry and eight feet in longshoring operations.

In addition, OSHA requires that fall protection be provided when working over dangerous equipment and machinery, regardless of the fall distance.

Does Gargoyle comply with OSHA?

Gargoyle has been tested to meet or exceed Federal and State (OSHA) safety regulations.

Gargoyle has also been tested to meet or exceed the engineering standards created by CSA and ANSI.

What is the difference between active and passive fall protection?

This would include comparisons between; guardrails vs harness, guardrails vs fall restraint or guardrails vs fall arrest.

Passive fall protection is the type of protection that does NOT require any action by people. Examples include: Guardrails, Safety Nets, etc.

Active fall protection is the type of protection that requires training and direct connection to an engineered fall protection system or anchor point. Examples include: Body Harnesses and Lanyards, Anchor Points, etc.

General rule: Passive solutions are preferred to active ones. They represent engineering controls that keep people safe regardless of training level and awareness of a hazard.

Are guardrails more expensive than Horizontal Lifeline Systems?

The overall cost of ownership for guardrails is much lower than horizontal lifelines, when you factor in the cost of certifying employees for working at heights (every three years), anchor point inspections (yearly), lanyard and harness inspections (yearly), recordkeeping (ongoing) and other related inspections.

There is also the amount of time and resources that must be devoted to making sure these are all adhered to. Whereas, a guardrail system can be set up once and you are instantly compliant.

Is Gargoyle easy to install?

Gargoyle is incredibly simple to install and can be done easily by an inexperienced worker with simple hand tools.

Each system has labels that contain a QR code that links to a series of videos showing exactly how to install the system for maximum time savings.

Is Gargoyle certified by an engineer?

Each Gargoyle system comes with a stamped engineering drawing backed by the in-house engineering team at Factory Supply.

Can Gargoyle be painted?

Yes. Gargoyle comes standard as an aluminum system that is grey but some clients prefer it to be painted safety yellow. This is done in-house with a powder coated paint that is weather resistant.

Can Gargoyle be used as an anchor?

No. Gargoyle must not be used as an anchor. This is stated explicitly in the Gargoyle installation manual among other safety requirements.

Can Gargoyle be installed on a sloped roof?

Yes. This depends on how steep the slope is for standard systems (it must meet the standards and regulations for sloped roofs). However, custom systems are available for multiple applications including sloped roofs.

Truck Netting Systems

Fall protection systems developed for safe loading and unloading of flatbed trucks.

Gargoyle Warning (Bump) line Systems

Gargoyle freestanding systems for creating an OSHA compliant bump line.

Become a

Gargoyle Dealer

Custom rooftop solutions backed by our in-house team of Professional Engineers. Offer your clients a simple to install fall protection solution that requires no extra training or equipment.

Engineered Fall Protection

Catalogue

Details about all of our Gargoyle systems can be found in our Factory Supply Guardrail Catalogue along with safety statistics and other info.

Factory Supply

Supplier of Working at Heights Protection, Aviation Access Products, Netting Safety Systems and Material Handling products.

About Liftsafe

We focus on creating turnkey solutions that allow your employees to do their jobs safely while protecting your company.