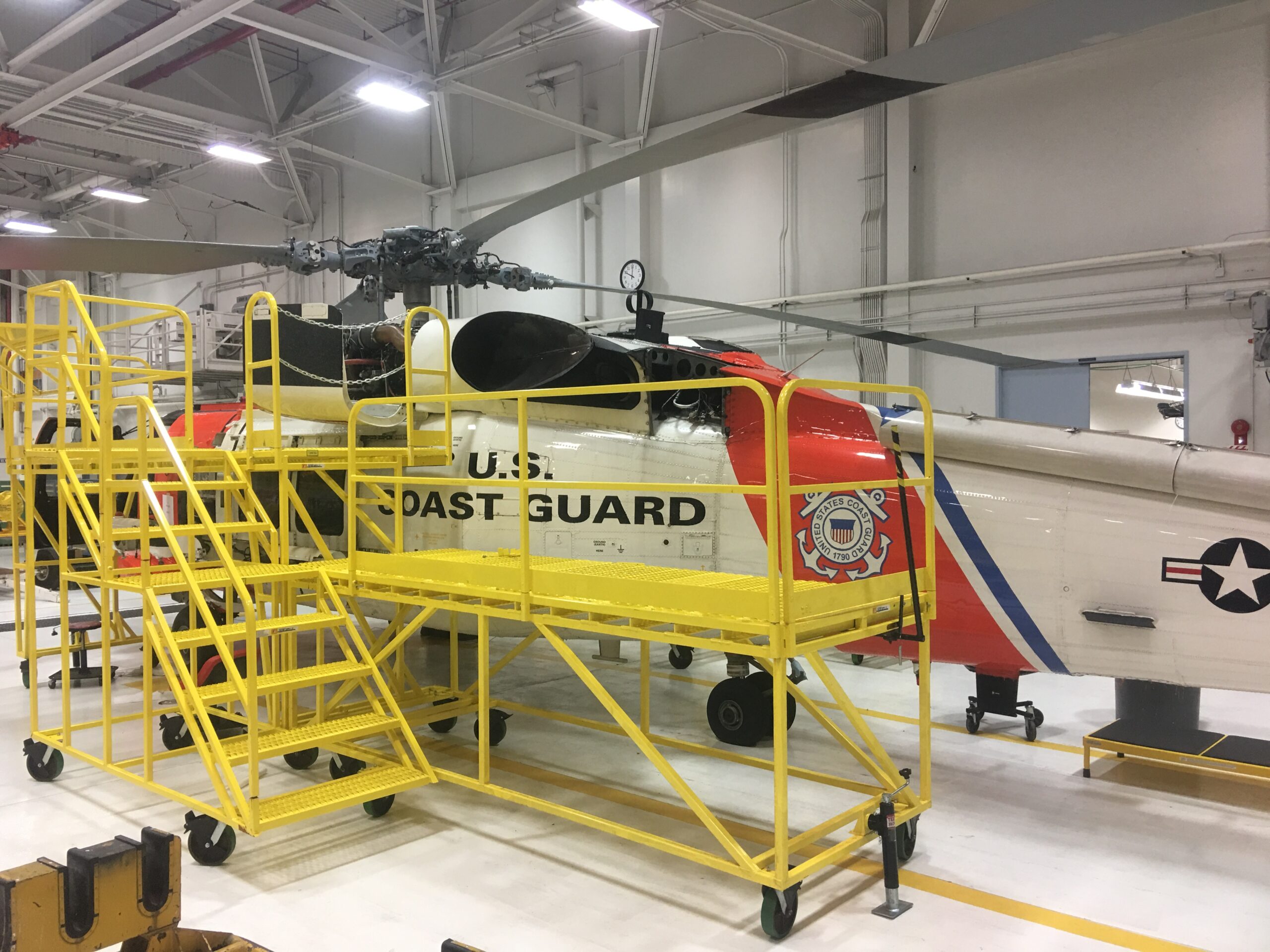

US COAST GUARD CASE STUDY

Providing safe access to hard to reach helicopter maintenance points for the US Coast Guard Air Station in Sitka Alaska.

CHALLENGES

- Employee safety

- Space issues

- Equipment damage

- Ergonomics

- Fall risks

- Hard to reach access points

SOLUTION

Provided 360-degree access to the clients helicopter with full coverage phase maintenance access stands. This stand was created for access to the engine, transmission, main rotor, tail rotor, and fuselage of the

Sikorsky S-92 aircraft.

OVERVIEW

USCG Air Station reached out to our team with a custom rotary wing access stand request. They required 360-degree access to their helicopter maintenance access points. This stand was created for access to the engine, transmission, main rotor, tail rotor, and fuselage of their Sikorsky S-92 aircraft. The aeroplane technicians needed a complete solution that covered every access point of the aircraft to perform a total oveahaul while protecting workers safety.

The Factory Supply team created a full-phase maintenance fuselage wrap-around stand with removable railings and 20-inch locking slide-out platform extensions. With a 1500-pound weight capacity per side, this access platform offered access to difficult-to-reach sections of the helicopter and safe access for two-person operations. The fit of the maintenance stand was fine-tuned through a protracted process of calls, emails, and several drawing revisions.

Customizations included right and left fuselage stands with a slide out tail rotor stand trap door and slot for tail rotor blade maintenance. These American-made Heli Grade Solutions are designed by our in-house engineering team to meet and exceed compliance standards such as ANSI and OSHA.

Safely accessing the fuselage, engines, main rotor and tail rotor maintenance points FOR 360-DEGREE COVERAGE.

The Factory Supply team

was professional and polite,

and provided a solution that

worked specifically for our

team.

— USA Coast Guard